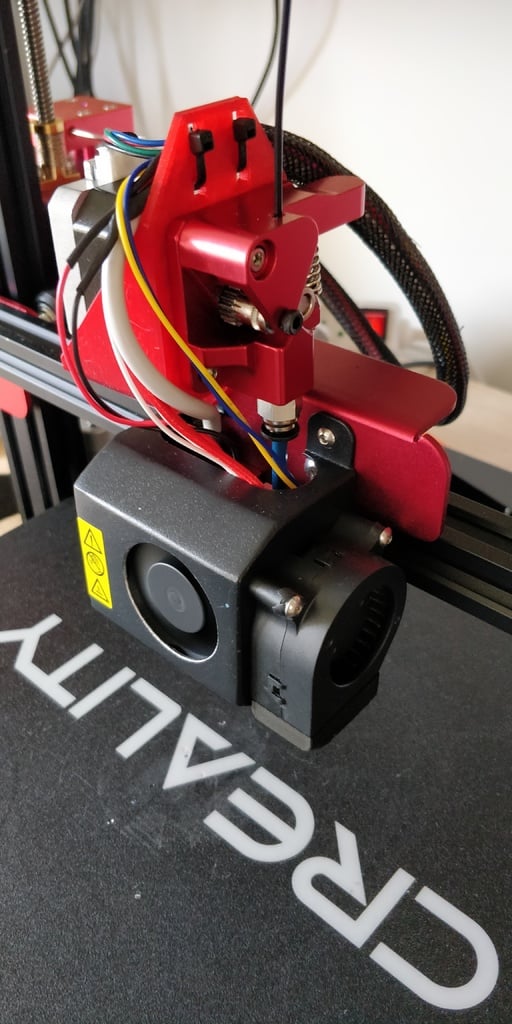

CR-10 S Pro Direct Drive

thingiverse

Here is an evolution that will change your life! I had many oozing and stringing problems with my CR-10 S Pro. After installing the MicroSwiss kit, I decided to change the bowden system in direct drive. This piece of plastic that you can easily print will allow you to place the extrusion system on the X carriage. Any modification of the firmware is necessary, the print volume will remain the same. The only two disadvantages are the following : - The filament detector will not work with this system but I'm thinking about evolution - Probe adjustment screw is difficult to access (but not impossible) All the stuff you need : - A 50mm PTFE or Capricorn tube (from the top of MicroSwiss heatsink to the bottom of the extruder) - 2x M3x10 Screws - 1x M3 washer - 1x M3 Nylstop nut - Nema 17 cable, about 30-40cm I’ve tested a lot of retraction parameters for Simplify3D software. The best results are with 2mm retraction @ 80mm/s. I am going to think about other improvements to guide the filament and detect the break. Enjoy !

With this file you will be able to print CR-10 S Pro Direct Drive with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CR-10 S Pro Direct Drive.