CR-10S Pro Z Sync Stepper Lift Mounts

thingiverse

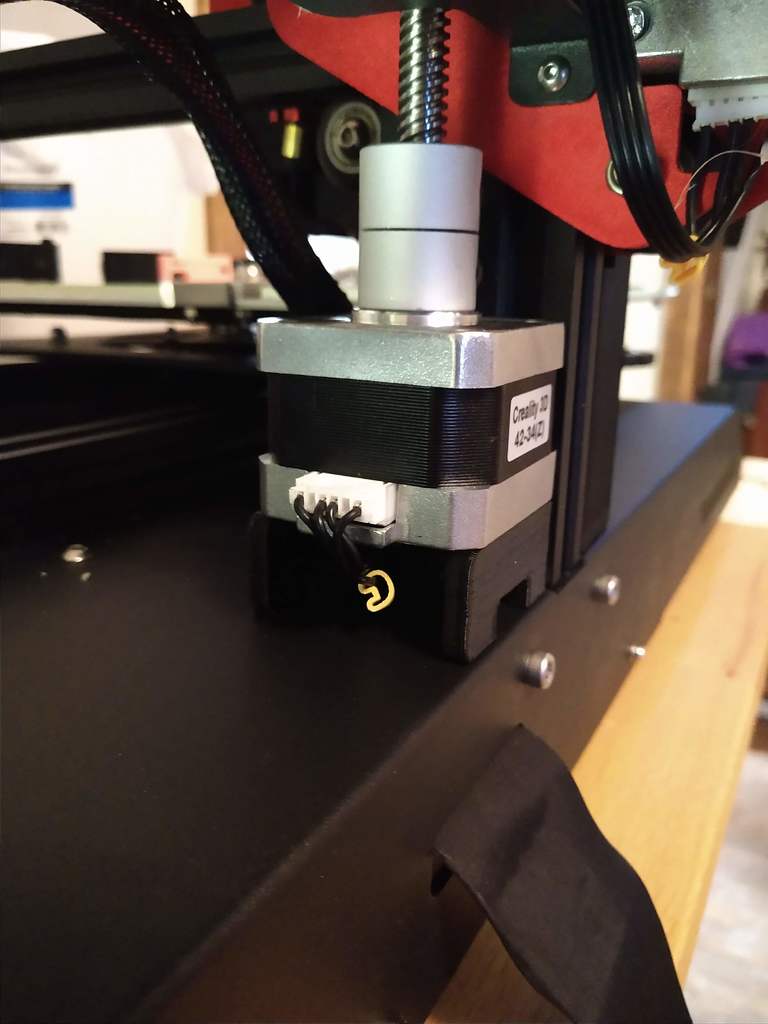

Synchronize your CR-10S Pro Z Axis steppers without losing print capacity or risking damage to your printer! **Edit 3/3/19:** Per request, I have added V2_Beta (As it is untested at this point) to allow socket head cap screws to be used to mount the stepper motor to the lift mount. This involved increasing the counterbore for these screws from 5.5mm to 6.25mm and shrinking the holes used to mount the lift to the 2040 uprights from 5mm to 4mm due to clearance issues. Please comment if you try this version so I know if it works or not as I don't plan to test it. After installing the Z Timing Belt Sync (https://www.thingiverse.com/thing:3387741), I noticed that I had reduced my overall Z height. The X carriage would hit the bearing block since it was lower than the stock one. This reduced my overall printing height by 23mm to 377mm, which doesn't seem like a lot, but I paid for 400mm! I am glad I noticed this before I decided to print a tall model. To work around this issue, I have designed a lift mount that replaces the stock Z stepper mounting plates. No permanent modifications required to fit these lift mounts. Allows the use of the OEM lead screw bearing blocks, but it is highly recommended to use the bearing blocks from the original Z Timing Belt Sync (https://www.thingiverse.com/thing:3387741) as they retain better belt tension than OEM . The lead screws will be raised and the timing belt will ride above the top rail of the printer, so be sure you don't have anything mounted to the top rail that will get in the way. **Parts List** * 2x - Stepper Lift Mounts * 4x - 3x30mm screws * 4x - 3mm washers * 4x - 3mm T-Nuts *If you haven't already installed the timing belt Z sync, you will also need:* * 2x - 20T 6mm width, 8mm bore GT2 pulleys https://www.amazon.com/gp/product/B077GMKW1C/ref=ppx_yo_dt_b_asin_title_o02__o00_s00?ie=UTF8&psc=1 * 1x - 760mm x 6mm width GT2 Timing Belt https://www.ebay.com/itm/GT2-Timing-Belt-Fiberglass-Reinforced-Width-6mm-Pitch-2mm-for-3D-Printer-CNC/152834326397?ssPageName=STRK%3AMEBIDX%3AIT&var=452962531775&_trksid=p2057872.m2749.l2649 **Installation Procedure** 1. Raise the X carriage and place something under it to prevent the nozzle from sitting directly on the bed. These work perfect for this task (https://www.thingiverse.com/thing:3384054) and will be helpful when leveling the X axis when you're done. 2. Remove the Z axis lead screws by loosening the set screws in the coupler and turning counterclockwise to raise them out of the coupler. 3. Remove the screws holding the original Z axis stepper mount to the frame. 4. Pull the stepper out and unplug the wires running to it. 5. Remove the two screws holding the OEM mount to the stepper. Set the mount aside, but keep the screws handy. These 3x16mm screws will be used to fasten the new mount to the frame. 6. Remove the two screws opposite of the electrical plug on the bottom of the stepper. (I have included wire cutouts so the plug will be facing away from the 2040 upright and run under the new mount and out the side). 7. Install the lift mount to the stepper using the 3x30mm screws. 8. Place the 3mm washers onto the 3x16mm screws from the original mount and run them through the mounting holes and loosely install the 3mm t-nuts onto the screws. Note that the holes are enlarged to allow some minor adjustment for proper alignment. 9. Slide the stepper into place ensuring the t-nuts are oriented properly to go into the rails. 10. Begin tightening the 3mm screws ensuring the t-nuts engage with the upright properly. Don't tighten these all the way as you will need to ensure the stepper is aligned with the lead screw. 11. Run the lead screw back into place and sit it on top of the stepper shaft. Now, adjust the mount until the lead screw is centered on the shaft. I like to slip the coupler on here to ensure they are aligned. 12. Finish tightening the 3mm screws to secure the mount. 13. Run the wiring through the wiring pass-through in the side of the lift mount and plug the stepper in. 14. Perform the same procedure for the opposite side. #Very Important! Applies to the left side of the printer only. If you completely removed the lead screw coupler, slide it back onto the stepper shaft, but do not tighten the set screw just yet. If it is still installed, loosen the set screw and allow it to slide all the way down and rest on the stepper. Remove whatever you used to support the X axis during installation. Lower the X carriage so that your nozzle is sitting on the print bed. While paying close attention to the black metal cover over the extruder wiring, slide the coupler up so there is a little bit of room between it and the metal cover. This will most likely be slightly lower than it was from the factory. The right side of the printer shouldn't have any clearance issues. 15. If you had already installed the Z axis timing sync modification, relocate the top bearing mount to the top rail or reinstall the OEM mount. 16. Reinstall the lead screw and tighten the set screw in the coupler. You should now have plenty of lead screw above the bearing block to install the GT2 pulleys and timing belt.

With this file you will be able to print CR-10S Pro Z Sync Stepper Lift Mounts with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CR-10S Pro Z Sync Stepper Lift Mounts.