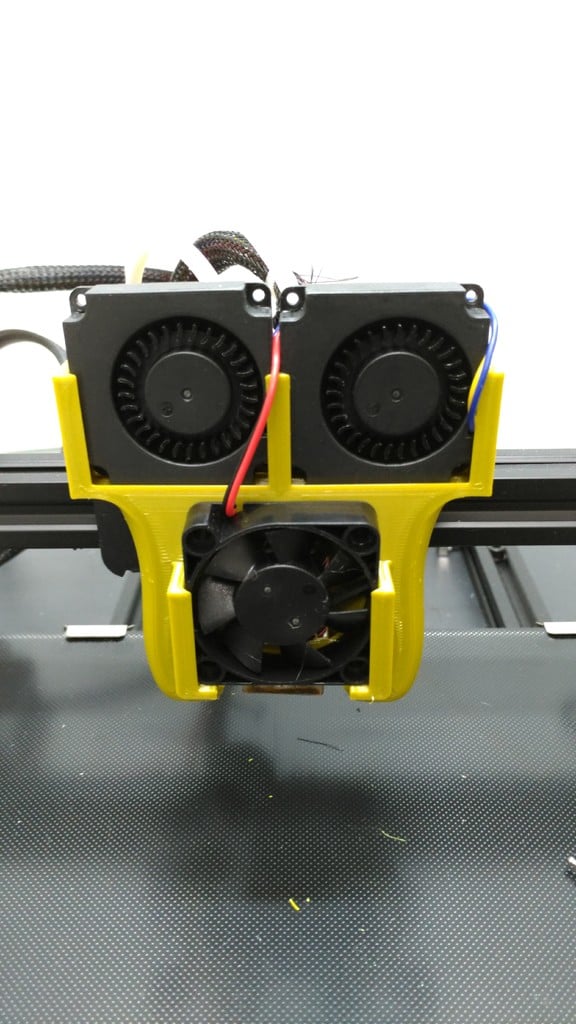

CR-X fan mount wind duct

thingiverse

This is a remix from my previous design Fan mount, wind duct https://www.thingiverse.com/thing:3256666 Because CR-X is with a round hot end and taller heat sink which will result in better cooling. I adapt my previous design on conformal wind duct to fit the requirement. There are two versions of the design 4010 cooling fan + 4010 blower fans and 4020 cooling fan + 4010 blower fans both have a side version of add-on mounting holes. crxdualfamowidu.STL is 1 4010 cooling fan, 2 4010 blower fans. crxdualfamowidumo.STL is 1 4010 cooling fan, 2 4010 blower fans and 2 sets of mounting holes. crxdualfamowidu4020.STL is 1 4020 cooling fan, 2 4010 blower fans. crxdualfamowidumo4020.STL is 1 4020 cooling fan, 2 4010 blower fans and 2 sets of mounting holes. A well designed fan mount + wind duct + add on provision for many 3d printer hot ends. A good design must 1. Efficient on cooling § Hot end cooling duct conformed from fan blade circle to heat sink rectangle, making 100% air go through heat sink. §. Filament cooling fan partially share duct wall with hot end cooling duct to shorten the distance from fan to duct outlet so not to lost too much pressure. § The filament cooling duct pointing bullseye to hot end tip from both sides. §. Filament cooling fan is placed in high place so to take cooler up above air. § Hot end cooling fan is placed as high as it can be and with an optional hot air defender. 2. Easy to print. § It is designed with “easy to print” in mind. You need to have support while printing, but the support is only 4mm high. § Bridging is reduced to very short distance so you won’t fail on that. It’s difficult to fail when printing them. § Two hooves in front of duct ends is for better adherence to print bed and you should cut them off after finishing printing. § You can either remove or leave the support on. It won’t affect the installation. 3. Light in weight, compact in size, sturdy in structure. § All 4 models are less than 20 grams. § With conformal duct design, greatly shrink the dimension needed without sacrificing any performance. § Because it is compact, it is quite sturdy. The thick of the screw holes is 4mm. 4. Easy to install. § Doesn’t need any screws except two for locking the hot end (with 4mm thick, you need longer ones). § For all fans, you just insert them into their positions. 5. Fits for more different machines and requirements. § The design is hot end depending rather than machine depending. As long as the two screw holes of hot end is between 14mm to 16mm, you can install it. § 4 different models to satisfy different requirements §§ 1(h.e. cooling fan) + 1(flm cooling fan) §§ 1 + 1 + 2(add on provision mounting holes) §§ 1 + 2 §§ 1 + 2 + 2 § 2 sets of add-on function mounting holes. The bigger hole is 7.2mm x 7.2mm. The smaller one is 2.8mm x 2.8mm. They are 14'll apart from the center of each square. 6. Very good visibility to print tip. 7. Fun § Fun thing for 3D printing is to design and make it. So, you still have the fun to design add-on shafts and make it come true.

With this file you will be able to print CR-X fan mount wind duct with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CR-X fan mount wind duct.