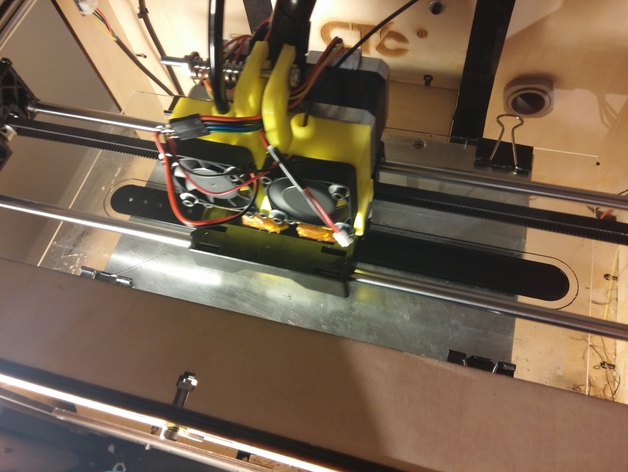

CTC replicator dual extruder for flexible filaments

thingiverse

For those who prefer stronger handles for flexible filaments, this dual extruder design offers a sturdy foundation that securely supports the filament throughout its path. By easily adjusting the height of your throat pipe, you can fine-tune the setup to suit your printing needs. This custom build was printed with 40% infill and three layers of perimeter lines at 40 mm/s for an extra layer of quality control. For users curious about my experimentation outside of the built plate boundaries, I must note that Simplify3d proved its worth in creating an adaptive slicing experience without sacrificing performance. I've updated the original model to add a much-needed feature – the extruder assembly knob is now integrated and waiting for you within the latest design. For fellow print enthusiasts, uploading this new file will ensure seamless alignment of all critical components. Upon reviewing multiple printing cycles with ABS filament, it became apparent that the right balance must be struck between quality and resilience. The following tweaks can greatly enhance durability: use 100% infill when crafting arms rather than relying on a 40% filling to achieve maximum stability. In addition to fine-tuning your extruder's design and material selection, make sure to update the G-code accordingly. I found that a customized G-code set greatly streamlined our build process. Simply copy these modifications into your system and enjoy smooth printing experiences with fewer setbacks. Here is what needs assembling for a robust build: acquire 623zz bearings, eight M3 x 35 mm screws, four 30mm screws of the same calibre, six smaller diameter (M3) nuts, sixteen M3 washers (specific to print assembly needs), and one longer length M4 bolt to attach critical parts in unison. Secure all M4 fasteners for tension control through the extruder tension mechanism that connects two motors at perfect opposition to ensure optimal pressure while printing delicate objects. To your success lies not just having proper instructions – it begins with an eye towards precise fit, where slight imperfections like under-width drill guides must be widened by a fine drill tip in a slow drilling method to suit specific tolerances found within modern manufacturing technologies available for consumers and businesses. A reminder of what works perfectly for those without extensive workshop space - use the adhesive hold created through clamps – no custom hardware required in many simple designs!

With this file you will be able to print CTC replicator dual extruder for flexible filaments with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CTC replicator dual extruder for flexible filaments.