Customizable Dual Extrusion Nozzle Offset Calibration Tool

thingiverse

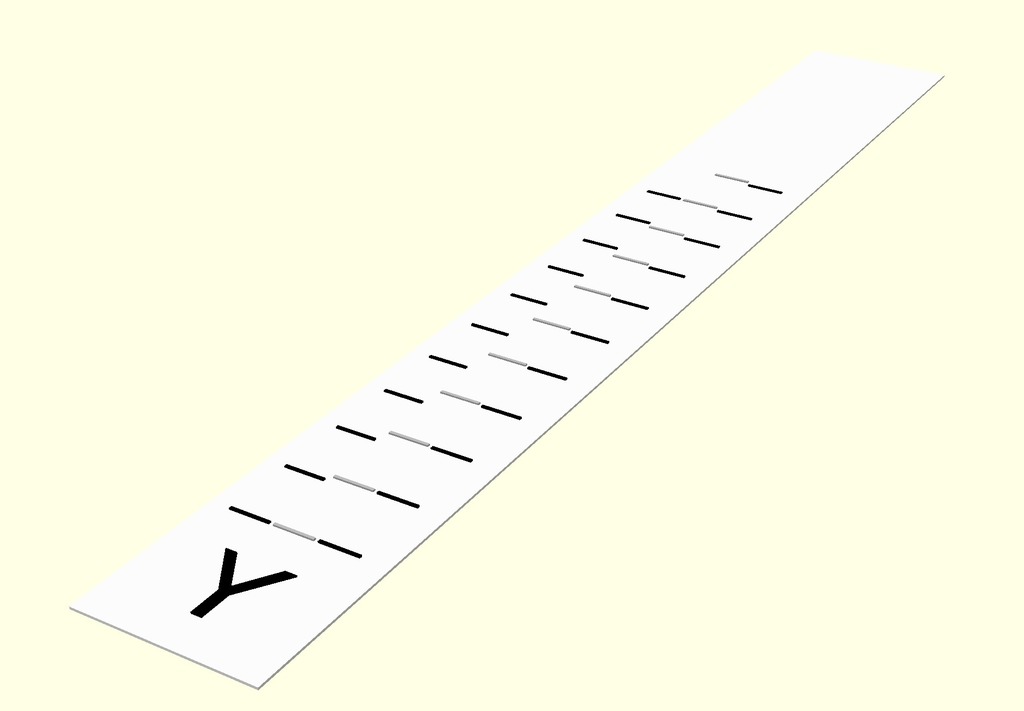

A calibration tool to determine the offset of two nozzles in a multi nozzle printer. Most articles on the topic indicate this is a herculean undertaking. Once the multi nozzle print head is installed, print these scales–aligned to each axis–to measure the nozzle offset in that direction. Once the offsets are determined, the printer's firmware may be updated with the final measurements and the slicer settings returned to 0. [Vernier scales](https://en.wikipedia.org/wiki/Vernier_scale) allow precision well below the nozzle diameter and likely to the movement precision of the X/Y axes themselves. The base and fixed scale are printed with the fixed nozzle (usually 0). The axis label and vernier scales are printed with the second nozzle. Any offset in the second nozzle will cause the vernier scales to align differently with the fixed scale providing a fairly precise measurement of the offset. The large version has vernier scales for 1mm (left) and 0.1mm (right). The small version 0.1mm (left) and 0.01mm (right). Unless there are more than two nozzles, the large scale should only need to be printed for one axis. Using a smaller nozzle size or contrasting colors for the base, fixed scale, and vernier scale may help with accuracy. ### Procedure for a two nozzle printer Depending on the offsets already in firmware, the large scale may not be necessary. #### Gross Adjustment 0. Measure (with anything... within 1cm is good enough) the offset between the nozzles along the large offset axis (most likely X). 1. Configure slicer settings to include this offset. For Ultimaker Cura 4.0.0: a. Go to _Settings_ -> _Printer_ -> _Manage Printers..._. b. Click _Machine Settings_. c. Switch to the _Extruder 2_ tab. d. Enter the offset in the _Nozzle offset \[X|Y\]_ field for the axis measured. 1. Print the large scales. 2. Adjust the offset in the slicer configuration with this new reading. 3. Repeat 3-4 until within 1mm. #### Fine Adjustment 0. Print small scales. 1. Adjust settings based on new measurement. 1. Repeat 1 and 2 until within 0.01mm. 2. Repeat 1-3 for the other axis. Most likely–for the highest accuracy–this process will require a total of 6 prints on a dual nozzle printer. Four for the axis with a large offset (two large, two small), and two for the smaller axis offset. For most purposes, one print of the large on one axis and one of the small on each axis may be enough. If print bed space allows, a scale for each axis may be printed at the same time.

With this file you will be able to print Customizable Dual Extrusion Nozzle Offset Calibration Tool with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Customizable Dual Extrusion Nozzle Offset Calibration Tool.