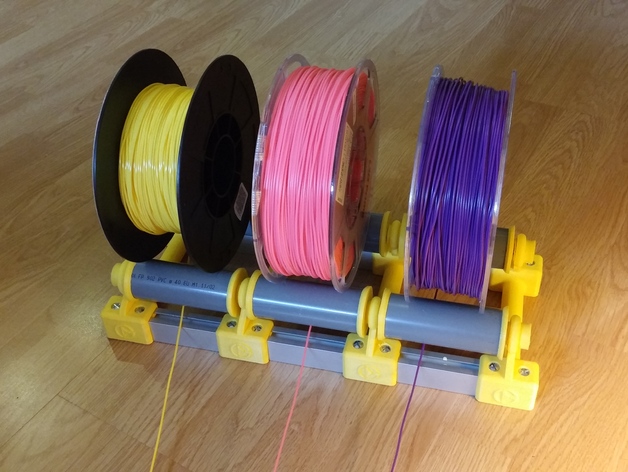

Customizable multi spool stand

thingiverse

This thing was inspired by a design on Thingiverse: http://www.thingiverse.com/thing:999840. I encountered the same problem after buying a diamond hot end for my Hephestos Prusa I3. A kind person suggested recycling materials from home, which led to using a curtain rail as the main support and copper pipes for the axis, while PVC pipes served as rollers. To make it easy for others to customize the design with minimal effort, I created a customizable version using OpenSCAD. You can tailor it to fit your existing materials, even if they differ from mine. STL files are included as examples, but you'll likely need to adjust them to match your materials. Print Settings Printer Brand: RepRap Printer: Hephestos Prusa I3 Rafts: No Supports: Yes Resolution: 0.2 mm Infill: 30% Notes: Supports are essential for the links, while other parts don't require supports. Custom Section How to Customize? You can't customize it using Thingiverse's application because they only handle one SCAD file at a time. I have six main files and six utility files. To access them, download and unzip the MultiPoolStand-v006.zip file. The only file you need to modify for customization is custom-params.scad, which contains all the parameters controlling the models of the six main files. The main files are called SpoolStand-xxxxxxx.scad. They're meant for rendering each part individually, and no modifications should be necessary unless you encounter a bug or want to make changes to the design. In upcoming sections, I'll explain how to use the 22 parameters in custom-params.scad. The dotted lines in the schemas indicate that certain parts don't matter. All dimensions are given in millimeters. 3D Printer To avoid stuck parts during printing, the model includes a gap between parts (like the gap between the axis and bearings). This gap depends on printer precision; often, half the nozzle size is a good value because the gap is used twice between two parts. The printer gap parameter is PRINTER_GAP, which defaults to half my printer's nozzle size (PRINTER_GAP=0.2 for a 0.4mm nozzle). Rail Your rail must be a hollow part allowing nut cages to slide into it. I reused an old curtain rail, but you can use standard rails. Roller Pipe The only requirement is that this part should have a pipe and not a filled bar; the axis needs to go through it. I used a 40mm PVC discharge pipe for mine. Axis This is the easiest part: I used a copper pipe, but any threaded shaft will do the job as long as it fits in the roller pipe. Screw Here, we need dimensions for the screws and their associated nuts to fix links to the rail. Customization Parameters These parameters are completely arbitrary and don't have mechanical constraints. The last parameter is STOPPER_LENGTH. Stoppers are the extremities of rollers that go into the roller pipes, and this parameter controls how deep they go.

With this file you will be able to print Customizable multi spool stand with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Customizable multi spool stand.