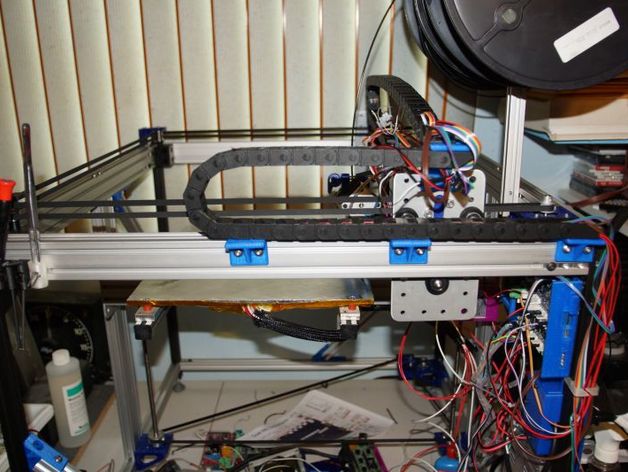

CXY-MSv1 CoreXY 3D Printer

thingiverse

A custom-made printer using Makerslide and a DuetWifi on 24vdc is being showcased. Please disregard the messy wiring, shown in this video link: https://youtu.be/llArYEVT2ow. Key updates include: 9/18/16 - The x-carriage has been modified to a double plate design, with corexy-x-carriage.scad featuring mounts for BLTouch and dc42's ir sensor. A proximity sensor version is available for 19mm diameter. 9/23/16 - Additional photos of the rear of the x-carriage are included. 10/1/16 - Mounts for E3D's Titan Extruder with a E3DV6 hotend have been added, along with stl files that include mounting for the ir bracket to use DC42's ir sensor. The scad file also includes proximity and BLTouch options. 10/15/16 - blower.scad has been updated for the Titan extruder mount. 11/7/16 - Idlers were added to the z bearing mounts to allow the belt to wrap around the leadscrew pulley more efficiently. A stl file is available with just two bearing mounts for replacement printing. 11/26/16 - Clips have been added to hold a led strip to the bottom of the x axis makerslide. 2/15/17 - Updates since the last update were uploaded. 8/10/18 - The code has been cleaned up and corner-tools.scad is now in use. A rar file (CXY-MSv1.rar) contains all scad files, while another rar file (CXY-MSv1 STL.rar) includes all stls. The GitHub repository is frequently updated: https://github.com/StephenRC/CXY-MSv1. Key hardware specifications include: All horizontal 2020 and 2040, as well as vertical and horizontal makerslide ends are tapped for 5mm. The vertical extrusions have eight tnuts in each channel, with four in the rest. A spool holder is available: a 300mm 2020 with two screw access holes in the bottom to mount it on the top rear 4020, along with an 8mm hole in the top for an 8mm threaded rod long enough to hold a spool on each side. Using http://www.thingiverse.com/thing:1647748 to hold the spools. On the bearing brackets from the top, the following components are used: M5x50, bearing support, washer, 2xF625Z,2x washers,2x F625Z, M5 nut. If metal couplers are used for the z-axis, a 4mm ball bearing should be placed in between the TR8 and stepper motor shaft inside the coupler. The bearing will allow tilt without changing the length. An alternate lighting method is to use a 5050 LED light string stuck to the bottom of the y axis makerslide. Blower.scad uses http://www.thingiverse.com/thing:387301, while Litemount.stl holds a 70mm LED ring in http://www.thingiverse.com/thing:8211. The LM2596 buck convertor is used to get 12vdc to power the ring. The feet are available at http://www.thingiverse.com/thing:15880, while the 400mm x 300mm 1/4" MIC-6 AL plate bed uses three short 2020 to support the bed. The bed spacers are made from silicon tubing and the heaters used are keenovo 200x300 600w 110vac silicon heaters. Print Settings: Printer: Custom-made Resolution: 0.2mm layers Infill: 25% Notes: PETG was used for anything exposed to heat, while PLA is used for everything else.

With this file you will be able to print CXY-MSv1 CoreXY 3D Printer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CXY-MSv1 CoreXY 3D Printer.