Cyberwizzards Alternative X-end

thingiverse

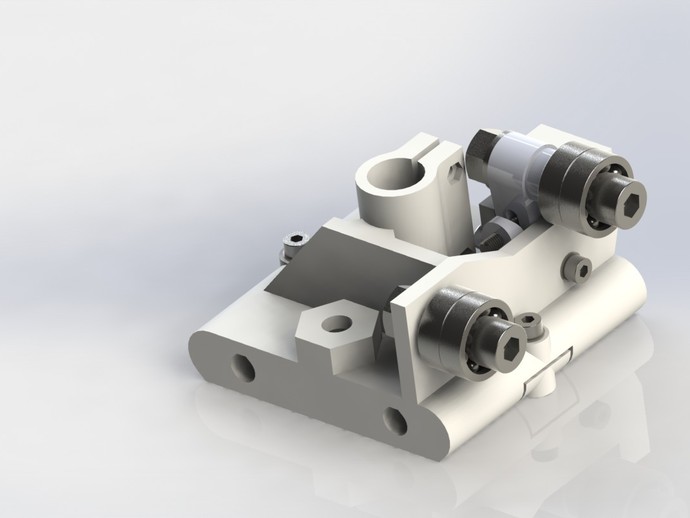

A warning, this is a prototype! The author redesigned Mendel's X-ends to accommodate a 22mm trapezoid or ACME nut and added a tensioner system. The goal is to maintain original Mendel length of smooth rod by placing the block longer than some MendelMax designs. Modeled in SolidWorks 2012, it uses 2 LM8UU bearings, clamped with 3mm screws, and 4x 608 bearings for belt path. Printing requires a heated chamber and possibly PLA, as ABS warping is an issue. Two versions are available: rounded and square base. Instructions include using a heated chamber, printing the parts in order, and optional additions like springs or secondary tensioners. Please print and share your feedback for further improvements!

With this file you will be able to print Cyberwizzards Alternative X-end with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Cyberwizzards Alternative X-end.