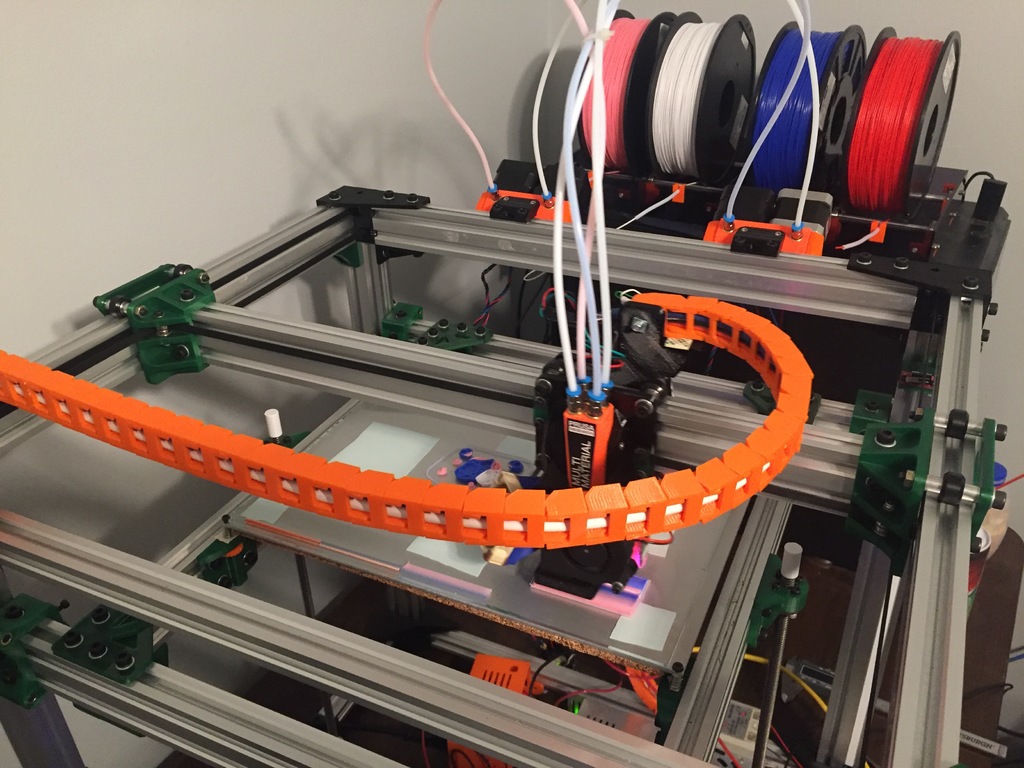

D-bot MMU

thingiverse

This is a high-tech upgrade for the C/D-bot and related printers, using the cutting-edge Prusa MK2/S Multi-Material Upgrade (MMU) kit. Required components: * Prusa MK2/S MMU kit * 4 x 600mm PTFE tubes * M3 and M5 hardware * Dupont crimp, pins & headers Optional components: * BL Touch * Drag chain * 40mm fan adapter for hotend The Prusa MMU kit parts are open-source, but the retail cost of the 4 x Bondtech gears is almost as much as the whole kit. Custom metal cooling tubes and other kit parts can be difficult to source. Firmware: A modified Marlin 1.1.6 firmware is included. Although 1.1.6 supposedly supports the motor switch board, I made some necessary changes to get it working. Note: You will likely need to edit the Configuration.h file, especially if you use a different size bed or don't use the BL Touch. Electronics: The motor switch board takes a 4-pin connection from the RAMPS board and outputs to 4 stepper connectors. When connecting steppers, keep in mind that the 2nd and 4th stepper cables must be reversed due to the motor/idler being reversed compared to the 1st and 3rd. Loading & unloading filament: Unlike a Prusa printer, this Marlin firmware does not have built-in LCD options for loading & unloading filament. You can do this using software like Pronterface or Octoprint. To load filament, push it into the extruder until it just enters the gears, then send a command to extrude 660mm of filament so that it stops in the middle of the metal tube. Note: If you have "prevent cold extrusion" enabled, you need to either heat the hotend to print temp or send M302 P1 first. To unload filament, first send Tn command (where n is 0-3), then "print" the unload gcode attached here. This does a special ramming & tip forming procedure to ensure the filament is loaded and shaped correctly for the next print. Printing: Use Slic3r multi-material edition or KISS slicer with the Prusa MK2 MMU print settings. I increased retraction to 6.5mm due to the longer Bowden tubes compared to the Prusa MK2. You can probably increase speed quite a bit later, but it's best to start slow until you get the feel of things.

With this file you will be able to print D-bot MMU with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on D-bot MMU.