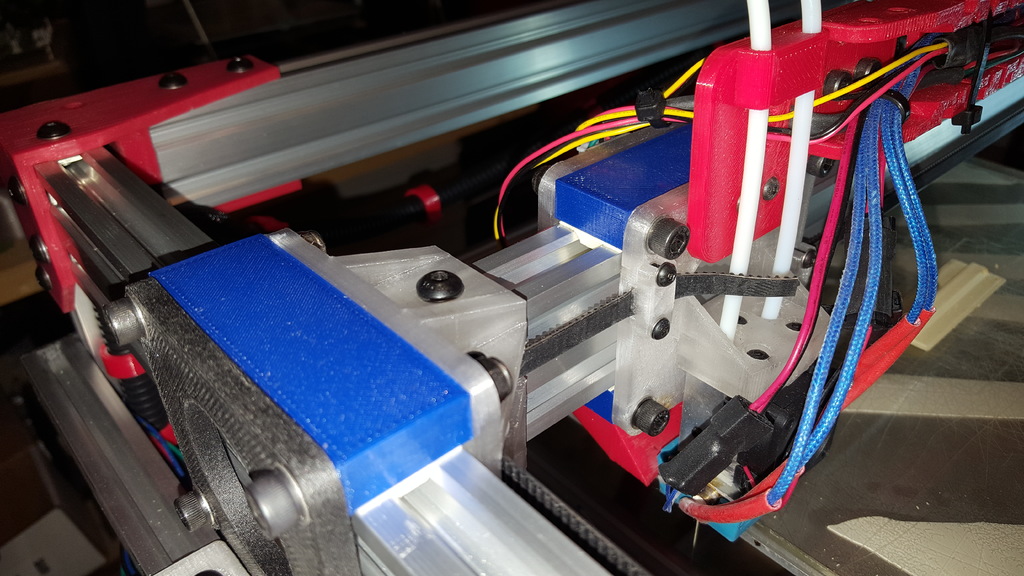

D-bot X/Y motion system linear guide blocks and pads made from Igus tribofilament

thingiverse

Note: I just posted a version 2.0 of these Igus sliding blocks on Thingiverse, which refines the design to blend in better with the existing D-bot print carriage plates and gantry bar end plates. I've had my D-bot up and running for several months now, and after some trial and error, I came up with a design that works well. My printer is busy most days of the week, and these blocks have held up great. They are a decently tight fit on the OpenBuilds V-Slot rails used in the D-bot's framing. I originally had an idea to use two shorter pads at either end of the sliding block, but it was difficult to get all four pads exactly aligned with each other. The full-length pads I ended up using allowed for extremely good alignment. As printed, there is some slight blobbing at the corners that requires a couple of minutes' worth of cleanup with an Xacto knife. Depending on how you print these, you may have to do some minor trimming to get the pads to snap down onto the tangs on the block. I left the tolerances extremely tight so that the pads would be exactly aligned on the bearing pads. Once printed and test-fit to each other, I put a few drops of CA (super glue) onto the Igus filament pad bottoms, snapped them onto the blocks, and then clamped them down pretty hard onto a section of spare 2040 V-Slot rail. I left them clamped hard like this for a couple hours until I was sure the CA was dry. I printed the blocks from PETG at 97% infill. I printed the pads from Igus tribofilament i170 at 70% infill with 3 perimeters in order to save material. I used 7 top layers at .1mm layer height, for fine resolution on the pads' bearing surfaces. I've also tried the i180 filament. The 180 filament prints easier and looks better, but it seems softer than the 170, and the 170 has less friction. Igus claims in their marketing materials that 170 has the best wear behavior, but is more demanding of production technique. I can vouch for at least the second part of that. I printed the Igus pads at 260 C with the bed at 90 C. I used a brim to lock it down after several attempts peeled up from my PEI sheet a little in one or two corners. I removed the brim with an Xacto knife afterward. I also used a brim on the main PETG blocks for the same reason. This is version 1.0 of this item, which I'm putting up now as is so that people can use it. My intent was to clean up the design of the blocks so they blend in better with the existing D-bot print carriage plates and gantry bar end plates. When I've refined the block design, I'll post that updated block as 2.0. Here's a short YouTube video showing this system in use on my D-bot: https://www.youtube.com/watch?v=ChPcBsqxBR4&feature=youtu.be I'm attaching my SolidWorks 2016 source files for both blocks and pads. All of this is released with the Creative Commons - Attribution - Non-Commercial license. Here's a link to version 2.0: https://www.thingiverse.com/thing:289381

With this file you will be able to print D-bot X/Y motion system linear guide blocks and pads made from Igus tribofilament with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on D-bot X/Y motion system linear guide blocks and pads made from Igus tribofilament.