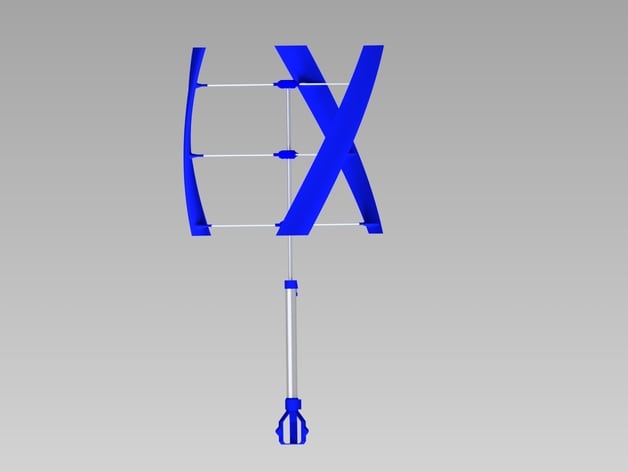

Darrieus VAWT - Wendel/S

thingiverse

Old water bottles are a huge environmental problem in several areas of the world. Those bottles are made of PET and are therefore not biodegradable. The good news are, that PET is (relatively) easy to recycle. Against this background, I designed a vertical axis windturbine (VAWT) for my master thesis. The requirements for this turbine are: printable with a "standard" Desktop-3D-printer (in this case a MakerBot 5gen) all parts necessary should be available in developing countries cheap easy to repair enough power to charge a Smartphone The turbine has three helical blades with an DU-06-W-200 profile, developed by the Delft University (1). Each blade consists of five elements and a top and bottom cover. To save material the parts are created hollow and are stiffened with struts and rips. The parts are connected by notches, lips and a wire rope (I used bowden cables from bikes) . A bike dynamo is used as a electrical power generator. The benefits of using bicycle equipment is the low price and availability at almost every point of the planet. As a shaft I used a threaded rod (M16). The problem with threaded rods is to find a straight one, but it is easy to develope a prototype with it. To measure the rotational speed (which is proportional to the power output) I set up a Raspberry Pi with a hall sensor. More information will follow soon. These will contain: power/wind measurements more information about the blade parameter building instructions a parts list more picture/videos maybe the complete thesis (in German...) 1)http://lr.home.tudelft.nl/fileadmin/Faculteit/LR/Organisatie/Afdelingen_en_Leerstoelen/Afdeling_AEWE/Aerodynamics/Contributor_Area/Secretary/M._Sc._theses/doc/2006_1_17.pdf Print Settings Printer Brand: MakerBot Printer: MakerBot Replicator (5th Generation) Rafts: Doesn't Matter Supports: Yes Resolution: 0.2 Infill: 40 % Notes: The slim part of the profiles warps easily. If you have problems with it use a raft or brim. Use two or three shells. Post-Printing Benefits of Post-Processing A smooth surface increases the performance of the turbine. There are several options to archive this. Sanding is dangerous because of the thin walls. It is better do paint the parts with an epoxy resin and to sand it afterwards. The surface gets not only smoother, but also tougher.

With this file you will be able to print Darrieus VAWT - Wendel/S with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Darrieus VAWT - Wendel/S.