Davros CNC Milling Machine - METRIC

thingiverse

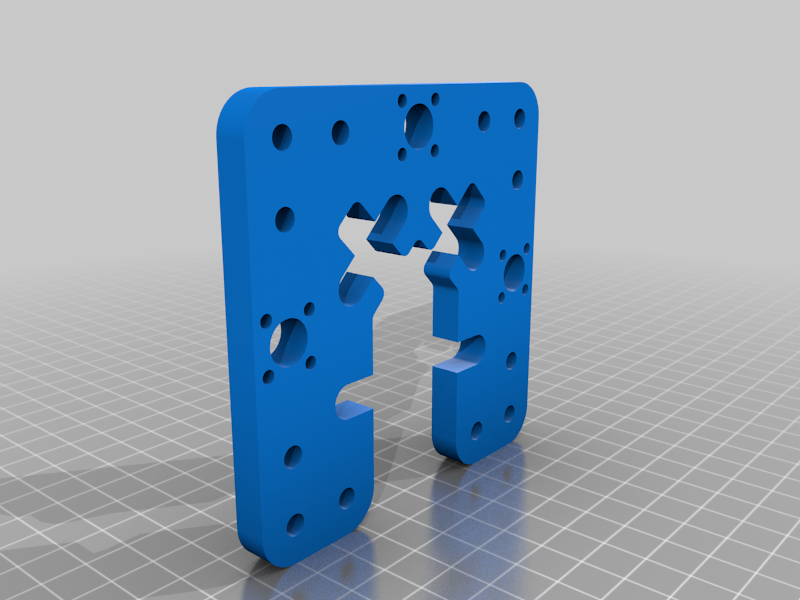

"If you can cut a hole in a kitchen worktop, you cam make a CNC milling machine!" ANOTHER BRITISH DESIGN... REQUIREMENTS; 40mm thick laminated KITCHEN WORKTOP (often salvaged from skips (called 'dumpsters' in usa) for free Standard Kitchen BASE UNIT/S as base ROUTER (also useful to MAKE and shape worktop) 20mmx20mm SQUARE SECTION TUBING 608ZZ / ABEK-7 STAINLESS BEARINGS (skateboard bearings) 8mmx20mm STAINLESS GROUND PINS (axles to bearings) Tensioners of Runners need WIRE GUIDE BEARINGS WITH V-NOTCH (sound on ebay and elsewhere) T8 THREADED RODS (as used on 3d printers) T8 ANTI-BACKLASH BRASS FITTINGS (as used on 3d printers) M5 BOLTS and NUTS Test WORKBED is 20mmx80mmx200mm ALUMINIUM EXTRUSION +T-NUTS to fit but I intend to go bigger PTFE SHEET NEMA23 MOTORS + CONTROLLERS (beefier than those in 3d printer) ARDUINO CONTROLLER (as used in 3d printers) MILLING CUTTERS ...and finally a set of 3d printed parts. ---THIS IS A WORK IN PROGRESS--- Thus machine uses LAMINATED parts, made up of layers of parts which could actually be laser, water-jet or plasma cut. Each is designed to require ZERO further machining... only assembly. This 'Laminar Engineering' style negates the need for left or right handed parts by simply inverting the parts and assembling them in a different order to make a left-hand or right-hand part. This keeps down the number of ACTUAL part profiles required. NOTE. This milling machine is intended to be able to cut at least aluminum and thus be able to replace all its own '3d printed' parts with milled parts, which you then pass on to a friend/someone-who-doesn't-annoy-you-as-much-as-your-other-acquaintances. The hole size ACTUALLY determines your WORK AREA as these parts can be fitted to ANY length of tube or threaded rod, as per your requirements. The Design; The intention here was to make a RIGID structure that can mill much like milling on the lathe, where chips fall AWAY from the work which is mounted VERTICALLY where the cutter lies in the SAME horizontal plane as the tool. There are distinct advantages to this approach. Instead of the current designs for home 3d printed milling where the tool can move away from the work or the work move easily away from the tool, here the work is BOUND within a LOOP of strong material, sandwiched between the tool and the frame which loops back around the tool. The forces on the work are ALL in one plane, into the frame, unless a 4th axis is fitted which may even be possible in future in this design layout. Unlike other home-built milling machines, cutting with the work-face upwards means chips accumulate on the work, clogging it up, here the chips can fall away into a tub in the base and a curved acrylic shield can be slid into position over the cutting position making it suitable for desktop use... although it embedded IN the 'desktop' rather than on it. It was originally intended to be strong enough to allow PLUNGE MILLING, the most cost-effective way to shift material quickly since most home mills lack the rigidity to do this. The design calls for 40mm kitchen worktop as the material of the 'ring' as this is the sturdiest, cheapest, easily available material accessible to ordinary people who don't live near a shipyard with access to slabs of 4in thick steel plate. 8) And often is it simply free, discarded. "If you can cut a hole for a kitchen sink, you can own a milling machine." was my original idea.... and the tool you can do it with is ALREADY your powerful milling cutter so you already HAVE most of what you need. Intentions. I hope you find this collection of parts useful. The project isn't complete because of a bereavement. I used to share my ideas with my last uncle, my uncle Donald, an elderly engineer, and although he didn't contribute to it, he was very excited when we talked about it often, and I kept going because he got such a kick out of it and was very encouraging. It fell by the wayside at his passing. 2020 has been an awful year. Let us start 2021 will the promise of something new and a fresh idea in this community, albeit an incomplete one, right now in 2020Dec. I am releasing these parts due to the excitement they caused and the feedback on a maker forum. I hope you find them useful and a good starting point for some springboard of activity in the coming year. Merry Xmas 2020 from Great Britain... if a tad early! Thank you for reading this far. I intend to return to this project in the new year, once other commitments have ceased.

With this file you will be able to print Davros CNC Milling Machine - METRIC with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Davros CNC Milling Machine - METRIC.