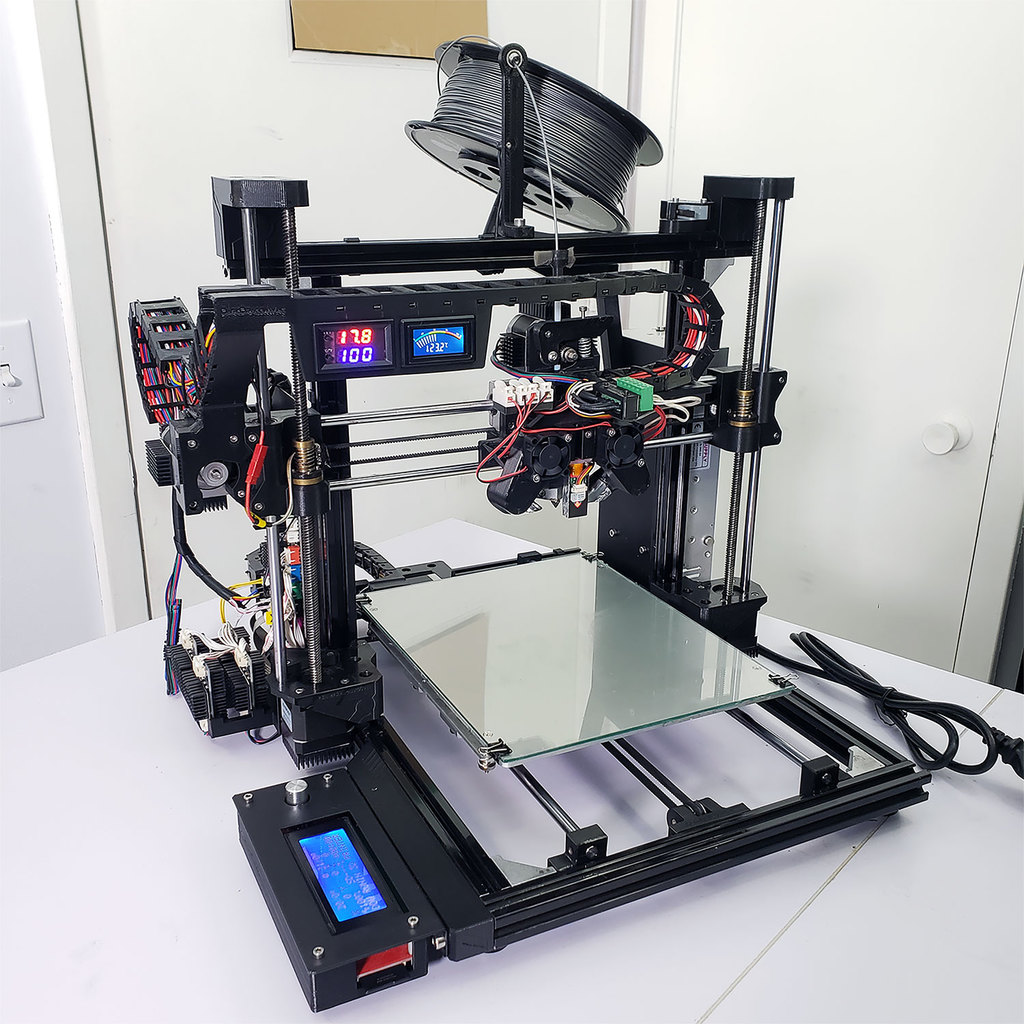

DDW Ronin 3D Printer (Hictop 3DP-12)

thingiverse

**UPDATE 4/28/22** **The old thing page doesn't show up for the public for some reason: https://www.thingiverse.com/thing:2116377** **This new page will be up until the old page is fixed.** **UPDATE 7/27/22** **We're now using Cura 5.1 version.** ___ **Website** https://www.darkdragonwing.com **YouTube** https://bit.ly/YouTubeDDW **Facebook** https://bit.ly/FacebookDDW **Online Store** https://bit.ly/ebayDDW **Product Recommendations** https://bit.ly/amznDDW ___ **Software:** Cura **Layer Height:** 0.2mm **Infill Density:** 75% **Materials:** ABS **Wall Thickness:** 1.2mm, 4mm **Top/Bottom Thickness:** Same as Wall Thickness **Filter Out Tiny Gaps:** ☑ or ☐ as you see fit **Compensate Wall Overlaps:** ☑ **Increase or decrease Flow Rate on some parts for a perfect fitment.** ___ **Nozzle Temp:** 250°C **Bed Temp:** 110°C **Bed Adhesion:** Glue Sticks **Enclosure:** 60°C ___ **Videos:** 3D Printer Modify video will be made sometime, but don't count on it. **Required Items:** https://bit.ly/3qQvf2r **Recommended Actions:** 1."DDW_RN-3DP27_Filament_Holder_50-55mm.stl" needs Density 5%, Wall Thickness 1.2mm, Top/Bottom Thickness 1.2mm. 2."DDW_RN-3DP34_X_Cable_Carrier_4.stl" is the only cable carrier file that needs brim. 3.Duplicate these: -2x DDW_RN-3DP22_Z_Nuts_Holder.stl -34x DDW_RN-3DP30_X_Cable_Carrier_Insert.stl -18x DDW_RN-3DP32_X_Cable_Carrier_2.stl -14x DDW_RN-3DP38_Y_Cable_Carrier_Insert.stl -12x DDW_RN-3DP40_Y_Cable_Carrier_2.stl -12x DDW_RN-3DP44_Frame_Cable_Clip.stl -3x DDW_RN-3DP45_Frame_Cable_Clip_For_Ribbons.stl -2x DDW_RN-3DP50_GT2_Belt_Tensioner.stl -2x DDW_RN-3DP51_GT2_Belt_Tensioner_Pusher.stl 4.Move Z axis frame assembly from 165mm(default) to 155mm. 5.Adjust the stepper motor current on the mainboard to X=0.8, Y=0.8, Z=1.0V, and E0=0.8V. Watch how to adjust the current here. https://youtu.be/8K3m6-kOoWw 6.After updating firmware, go to Control, Restore settings, and then Store memory. 7.Use some foam from the foam brush for the dust filter. 8.Use a soldering iron to press in the brass nuts. 9.Must use BL-Touch sensor. 10.Must use filament run-out sensor. 11.Must use 324MM integrated lead screw Z stepper motors. 12.Set Auto Cool Down: -Press and hold the Set button. -Press the Set button again 1 more time to get to P1. -Press both Set and C/F buttons at the same time. -Keep pressing the C/F button until you get to 0.1. -Wait 5 seconds. -Press the Set button, then press and hold the Set button until you get to 100. -Wait 5 seconds and then you're done! The printer will stop printing and cool down when the temperature reaches 100°C at the heat sink. **Software:** Arduino (for updating firmware) https://www.arduino.cc/en/Main/Software Cura 5.1 (for generating 3D printing codes) https://github.com/Ultimaker/Cura/releases/tag/5.1.0 FreeCAD (for designing 3D parts) https://www.freecadweb.org/wiki/Download **Firmware:** DDW_RN-3DP_FIRMWARE_10_28_20 https://drive.google.com/file/d/1fMX-iDTapfBW1y1J7jNgam6LtaJCZI1b/view?usp=sharing **Ronin 3D Printer Specs** 24V Bed size 210x270x225mm (XYZ) Integrated lead screw Z stepper motors Filament run-out sensor BL-Touch sensor TL-Smoother Auto bed leveling Auto cool down when the heat sink fan fails Auto shutdown after the print is done Ambient temperature monitor Strong 75% infill ABS Parts A spool holder with ball bearings Easy cable chain system **Printer Info:** E-Steps: 94.4962144403 Width: 210 Depth: 270 Height: 225 Firmware: Marlin RC8 **This printer is now very stiff, fairly accurate, and has little to no play. However, there is a flaw in this style of 3D printer. With the increasing weight on the Y axis, there will be more ringing artifacts on the print. You can avoid ringing artifacts by printing slower on the skin, 15mm/s or less for this printer, but when the print gets heavier, the ringing artifacts may be more visible.** ___ Note: You're already getting these in the "Machine Settings RN-3DP Cura 5.1" file. ;Start G-code M107 ;Start with the fan off G21 ;Metric values G90 ;Absolute positioning M117 Check fans... ;Put message on LCD screen M106 ;Fans on G28 ;Homing M107 ;Fans off M117 Auto X leveling... ;Put message on LCD screen G1 Z15 F1800 ;--Level X rods (F value is mm/minute) G0 X210 Y265 F15000 ;--Level X rods G1 Z235 F1800 ;--Level X rods G1 Z15 F1800 ;--Level X rods G0 X25 Y68 F15000 ;Coming back for homing fast G28 ;Homing G92 Z0. ;Z offset lower = Z pos, lift = Z neg M117 Auto bed leveling... ;Put message on LCD screen G29 ;Run auto bed level during cool bed tempersture G1 Z150 F1800 ;Move Z up M104 S{material_print_temperature_layer_0} ;Start heating extruder M140 S{material_bed_temperature_layer_0} ;Start heating bed G4 P2000 ;Delay 2 seconds for LCD message M109 S{material_print_temperature_layer_0} ;Wait for extruder to reach temp before proceeding G4 P2000 ;Delay 2 seconds for LCD message M190 S{material_bed_temperature_layer_0} ;Wait for bed to reach temp before proceeding G4 P2000 ;Delay 2 seconds for LCD message M25 ;Wait for user M117 Ready to print? ;Put message on LCD screen G0 X105 F15000 ;Move X to center G92 E0 ;Zero the extruder G1 E10 F250 ;Extrude filament to nozzle G92 E0 ;Zero the extruder G1 Z15 F1800 ;Coming down close to bed fast M117 Printing... ;Put message on LCD screen ;End G-code M104 S0 ;Extruder heater off M140 S0 ;Heated bed heater off G91 ;Relative positioning G1 E-10 F30000 ;Retract the filament a bit before lifting the nozzle, to release some of the pressure G1 Z+15 F1800 ;Move Z up a bit G90 ;Absolute positioning G0 X210 Y265 F15000 ;--Auto shutdown - Move bed to the front G1 Z235 F1800 ;--Auto shutdown - Move move Z up all the way M117 Auto shutdown... ;--Auto shutdown - Put message on LCD screen G4 P600000 ;--Auto shutdown - Delay 5 minutes for the hotend to cool down G1 X215 ;--Auto shutdown - Move X to trigger the power switch M84 ;Steppers off ___ **Weird Moves** - ***Problem:*** Printer keeps making random moves during print using SD Card. - ***Solution 1:*** Try using a new SanDisk Extreme 16GB SDHC SD Card. - ***Solution 2:*** Try using shorter 10 pin ribbon cables. 45CM or shorter is a safe length. The longer the cable, the more errors you will get. - ***Solution 3:*** The SD card reader might be bad. Buy a new 2004 LCD SD Card Reader. - ***Problem:*** If your HICTOP printer is making random weird moves and shutting down when using an SD card, it means that part of the LCD screen is touching the metal piece that is touching the Y step motor. If you have an old LCD screen that is all metal, you will have this problem. For your information, HICTOP now provides the metal cover that comes with plastic nuts to separate the LCD screen and the metal cover to fix this problem. - ***Solution:*** Remove the LCD screen from the printer frame and put it aside. Avoid the LCD ribbon wires touching the step motor wires. **Main Board & SD Card Reader** - ***Problem:*** From April 2017, HICTOP now has a built-in SD card reader on the mainboard. Thus, the SD card reader on the LCD is no longer usable. - ***Solution:*** Buy an MKS Base V1.6 3D Printer Controller Board to replace it. **LCD Doesn't Work** - ***Problem:*** LCD doesn't work when plugging into the mainboard. - ***Solution:*** Some Chinese MKS Base V1.4 or V1.5 mainboards have the EXP2 and EXP1 upside down, so just flip the EXP2 and EXP1 plugs upside down and force plugin accordingly. **Loud Converter** - ***Problem:*** Loud Converter fan. - ***Solution:*** Replace the fan with a new one which is a 24V 60x60x15mm fan. **ABS Bubbling** - ***Problem:*** ABS filament is bubbling when extruding. - ***Solution 1:*** Bake the ABS filament in the oven at 175F for 1 hour or 2 hours and then try printing. It really depends on how much moisture is in the filament. The more moisture, the longer the bake time will have to be. - ***Solution 2:*** If you don't have an oven, buy a dehydrator and dehydrate the ABS filament overnight with 158F or 70C. Cut a big enough hole on 3 trays, and you should be able to fit 2 1kg spools in there. **PLA Clogging Nozzle, Heat Creep** - ***Problem:*** PLA keeps clogging at the throat even with a new nozzle and a new throat. - ***Solution 1:*** Check the heat sink cooling fan, you may need to replace it. - ***Solution 2:*** If it's still clogging, try to increase the extruder spring tension. - ***Solution 3:*** If it's still clogging, try blowing cool air through the printer. - ***Solution 4:*** If it's still clogging, try printing at a lower temperature like 200C or 190C. - ***Solution 5:*** If it's still clogging, throw away your filament, and buy a better quality filament. **Heat Drops Randomly** - ***Problem:*** Heat drops and the printer stops. - ***Solution:*** Check the heat sensor wires, they might be broken inside somewhere. Just replacing the sensor would be the best solution. **Weak Z Motors, Repeat or Dipping on First Layer** - ***Problem:*** Z motors keep dropping on the first layer. - ***Solution:*** Clean up any build-up dust on the TL-Smoother boards by using a WD-40 Specialist Contact Cleaner Spray and blow them off again with compressed air. **Print Walls Aren't Smooth, Inconsistent Extrusion** - ***Problem:*** Walls on some big prints aren't smooth in some areas. - ***Solution 1:*** Clean up any build-up dust on the TL-Smoother boards by using a WD-40 Specialist Contact Cleaner Spray and blow them off again with compressed air. - ***Solution 2:*** Change your nozzle. - ***Solution 3:*** The part you are printing is thin and the layers may be too close or the overlapping is too great causing a temporary clogging on the nozzle on some areas. Turn on the "Compensate Wall Overlaps" option in Cura print settings. **Random Over Extrusion** - ***Problem:*** Random over extrusion on some layers at the same spots every print. - ***Solution 1:*** Try different filament from a different brand, the one you're using might have an inconsistency problem. - ***Solution 2:*** Try printing using a USB cable and see if the over extrusion will still occur. If it does, then there is possibly a problem with the SD card, SD card reader, or the mainboard. **Nozzle Keeps Clogging** - ***Problem:*** Nozzle keeps clogging, the drive gear keeps spinning, and the filament doesn't move. - ***Solution 1:*** The extruder spring lost its tension, maybe due to a deformed extruder X lever. Increase the extruder spring tension, replace the nozzle, and start printing. - ***Solution 2:*** Also check for unstable temperature. It may have just gotten too cold to extrude, then got clogged, and then back to normal temp. ___ ⚠️ Disclosure: This section contains affiliate links to products. We may receive a commission for purchases made through these links.

With this file you will be able to print DDW Ronin 3D Printer (Hictop 3DP-12) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on DDW Ronin 3D Printer (Hictop 3DP-12).