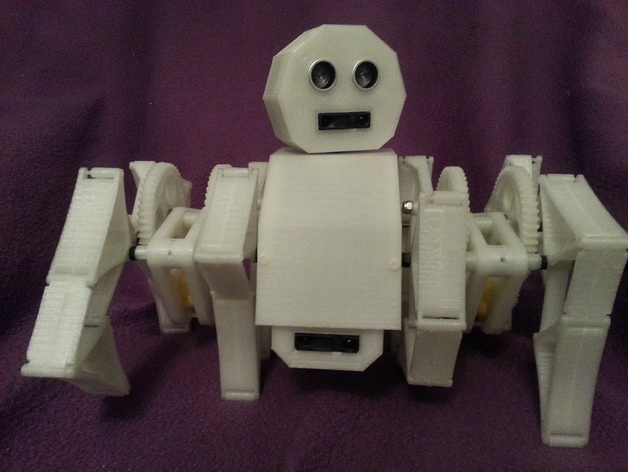

Deca - a walkerbot

thingiverse

Inspired by Theo Jansen's Strandbeests. After making the Glowstrand (http://www.coolkidsrobots.com/robot/glowstrand), I decided that I wanted to design something that was all mine... and with a big change, Mid Outboard Motors, using some cheaper more available gear motors. I got the motors from IC Station, but they are available in many stores. They must have the dual output shafts for this design. Deca is very fast, its going to need some excellent sensors and processing, I'm using a Parallax Propeller Quickstart board and a L9110S DC/Stepper Motor Driver Board for motor control. It also has eight 4 x 10 x 4mm ball bearings for the big gears. I used short pieces of filament for pins on all the leg joints, carefully melted over the ends to make them stay put. The frames are held together with four 125mm long pieces of m4 threaded rod, and a bunch of nuts and the 8mm and 11mm spacers. I used nylon nuts mostly. For the big gears, I used two 53mm long pieces of m4 threaded rod as axles, with m4 locking nuts. For the crank pins I used m4 nylon screws. You will need to drill and tap the holes in the gears. You will also need to clean up all the 4mm and 1.8mm holes in each part. You can see more here http://www.coolkidsrobots.com/robot/deca-son-glowstrand 12/10/15, updated the head with better path for wiring and sunk servo horn screw heads. 12/12/15 Added spacers for running motor power through the threaded rods and making a cleaner look (Connector_11x4mmSpacer.stl). You will need to find some set screws and drill and tap as appropriate. Then tin the ends of the wires before inserting and clamping them. 12/13/15 Added a mount for boards 12/20/15 I made a servo head for a RadioShack Ultrasonic Range Sensor and a Sharp IR GP2Y0A21YK0F Analog Distance Sensor. Recessed mounting holes for 9g servo horn, also has nice wire path. Also posted here:http://www.thingiverse.com/thing:1213658 Post-Printing BOM Ankle.stl - Print 8 of these and 8 that are mirrored thigh3D.stl - Print 8 of these and 8 that are mirrored Each half (mirrored pairs) to be pinned together with short pieces of filament and glued with super glue, you will need to ream out the pin holes with a 1.8mm drillbit dogbone3.stl- Print 8 of these and 8 that are mirrored Use small allen wrenches in the pivot holes to align and glue these halves together LongRod3D.stl - Print 8 of these MidRod3d_x.stl - Print 8 of these ShortRod3d.stl - Print 8 of these Pinion4.2-1.stl - Print 4 of these Spur Gear4.2-1.stl - Print 4 of these Shoe.stl - Print 8 of these OuterFrame.stl - Print 2 of these and 2 that are mirrored bodySide.stl - Print 1 of these and 1 mirrored bodyTop.stl - Print 1 of these 11x4mmSpacer.stl - Print 6 of these - or 2, see Connector_11x4mmSpacer.stl Connector_11x4mmSpacer.stl - Optional - print 4 - use for hiding wiring by using threaded rods for power to motors 8mmSpacer.stl - Print 8 of these DecaServoHeadv3.stl - Print 1 - will fit HC-sr04 sensor (16mm transducers 25.4mm apart) DecaServoHeadBackv3.stl - Print 1 EndBar.stl - Print 2 All the inner pivot points are 1.8mm will need to be reamed out with a 1.8mm drillbit and then when assembled use short pieces of 1.75mm filament as pins, carefully melt the ends to make them stay put. All the 4mm pivot pints will also need to be reamed out with a 4mm drillbit. I used a lot of nylon nuts and some metal and locknuts.

With this file you will be able to print Deca - a walkerbot with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Deca - a walkerbot.