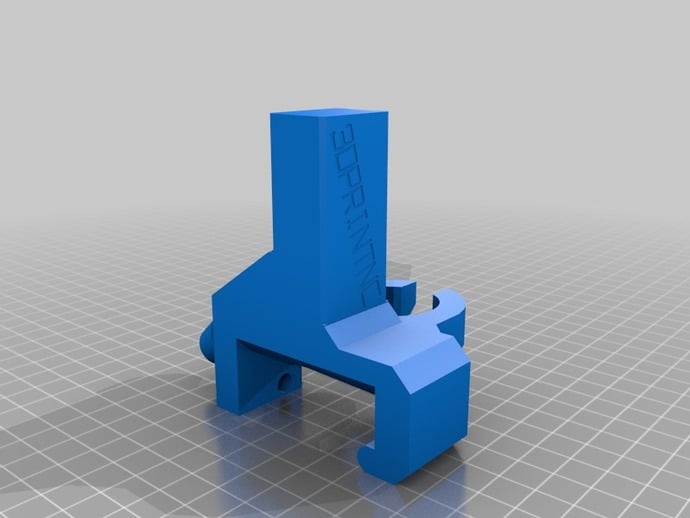

Decap tray for RCBS reloading press

thingiverse

A replacement tray for RCBS Rock Chucker Supreme's inverted "Y" is now improved to offer better support removal. It fits behind the ram and is retained by a frame slot and slotted ring around the ram. Ensure you remove the shellholder before installing or removing this tray. Choose either left or right side hose placement for the small bottle or plastic jug that holds spent primers and debris. The default version can be printed from STL files with 4mm brim in ABS or PLA, requiring support. Contact Info@3DPrintnc.com for questions or support. For printing, use a 0.25 to 0.35 mm layer height, ABS or PLA, with 0.3 rectilinear or 0.2 honeycomb fill, at least 3 perimeters and 4 top and bottom layers. Make sure your bed temperature is 10C above normal to prevent warping of ABS. Source files include a "wHS" option for heat shield to keep the piece flat on build tray during printing. Spent 22 cal case can be used to pin the part to press frame, but it's not necessary. Universal decap dies let metal pieces drop gently and sometimes clog up to 4 primers before dropping as a group. You can see each primer drop down the clear plastic tube.

With this file you will be able to print Decap tray for RCBS reloading press with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Decap tray for RCBS reloading press.