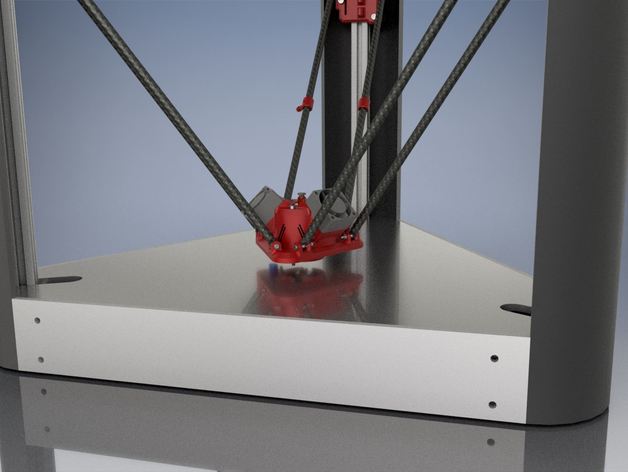

Delta 3D Printer

thingiverse

I've finally released my custom built Delta 3D Printer after many months of hard work in the machine shop, on the computer, and at the electronics workstation. Every single part of this amazing machine was designed and fabricated by me from scratch. Of course, I did draw inspiration from other printers on the market to make sure I got it just right. My goal was to create a printer that's big, affordable, fast, accurate, reliable, and easy to repair. Sounds simple, right? Wrong! There aren't many printers out there with all these features under $500-$600, my tight budget for building this printer. Stay tuned - soon I'll start selling this baby at Dimension 3 Printing! The main structure of the printer is made from sturdy 25mm 80-20 Aluminum extrusions, easily accessible for you to model and download here on my website. As for the electronics, I initially went with an Arduino Mega 2560 paired with a Ramps 1.4 board and Pololu stepper drivers. But later, I switched to the fantastic Azteeg X5 Mini, a 32-bit controller perfect for those pesky delta kinematics. The printer features beautiful 3D Printed carriages running on high-quality Openbuilds wheels along the grooves in the extrusion, giving you silky smooth and locked-in linear movement. The build volume of this massive machine is roughly 300mm in both X and Y directions and an impressive 430mm in Z direction. My custom extruder setup is truly unique - I paired a flying extruder with an E3D V6 hot end, driven by a NEMA 17 motor connected to internal gearing. It's fantastic for printing flexible filaments, easy to set up, and produces outstanding results! If you're wondering how it all works, take a look at the photos above. Now, I know what you're thinking - 'Why would anyone bother building their own 3D printer?' Well, every file is there to help make your life easier. And yes, some files were even created from purchased parts that I meticulously modeled for a perfect fit. Don't worry if it sounds complicated; trust me when I say it's all been taken care of! All you need now is a reliable source of electricity and some quality printing materials like PLA or ABS. Printing settings can be customized as needed but to give you a starting point, here are my preferred settings: - Printer: Delta 3D Printer - Rafts: Yes - Supports: Yes - Resolution: .2 or .1mm (your choice) - Infill: Around 40% - enough to give parts the rigidity they need while still keeping them from getting too heavy. - Notes: Feel free to experiment with other infill settings if you're more comfortable doing so. That's it for now. Stay tuned for future updates and I'll catch you in my next post!

With this file you will be able to print Delta 3D Printer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Delta 3D Printer.