Delta Bad Boy 3d printer

thingiverse

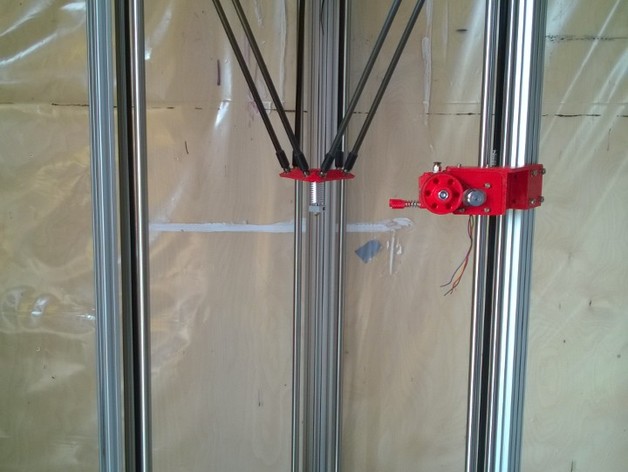

January 2016 Im back on track Again, I have now time to make the bot finish, Look for update in the NeXT month or so. Sorry for the delay of finish the Bad Boy, I got some health problems that set me back some months. Im now back and fit Again. New Motor Mount 11/7 .....V3 The effector.https://www.thingiverse.com/thing:716253 The Extruder incl. Mounthttp://www.thingiverse.com/thing:791325 The Delta "Bad Boy" 3D printer is under Construction. ALL the file is not ready for production. I printing all the file right now and adjust them one at the time. Ending of April all the file, Building plans, and Bom will be ready. Build size 400x800mm Steel rod 16mm. 88mm center to center. LM16LUU (16x70mm) Alu. extrution 20x60mm Frame size 600x1500mm Effector arms Dia.10mm. Steel ball Dia 12mm. Countersink magnet 15mm. 80mm center to center Enloser with front door and encloser heat at 50dg. Can do without. Things will be adjusted and new will come.. THE FILE IS ONLY TO SHOW MY PROJECT AND MABY NOT CORRECT .Download is okay but check the file. 12/1. All 3 Motor Mount is now printed. The file is also change from the orginal,. The new is V2. and is final, some older fill is gone. V1 Idler file is also final. I print it right now . All print with 50% infill. Note: The "platform" on the Motor Mount and Idler/top Mount is only for the print to stick to the heatbed. I use ther Dremel to take it away, you can leave the half circel if you want. 16/1. Uploaded a pic. of all the Motor Mount I made to find the right design for easy printing. 30/1. I start to build the Bot. I cut away the support piece on the print and start build the frame...It`s so great, and perfect allined. I orders a E3D V6 Hotend with "Volcano" head. Print size...0.8 - 1.2mm WE GO BIG, see the video. Made the Effrector end 12mm ball bearing to fit on 10mm Carbon tube 10OD x 8ID. Today I get the 128cm x 16mm Stainless stell rod...YES 12/2 I got the wrong Rod 12mm so Today the new came 16mm in 148cm. and change the hight to 1500mm build 800mm long. Still working on the IGUS integraded carriage. 22/2 Now the IGUS bearing is working with the Integrated carriage, and I can move on to Mount it. Pic. on the way 27/2 Carriage finish and working great 70mm center to enter. You can use IGUS or LM16LUU 70mm long. If u use Igus I made em 20mm long. I glue the bearings to the carriage with EPOXY. Effector was also finish. 50mm center hole. 6pcs. 3,5mm screw holes for Hotend Mount and 3 to Fan (from underside) 2/3 Photo of the new Effector and Carriage. 21/3 I Work on a new Effector and E3D Mount for V5 and V6. A fan mount too. I Also make a Rod Effector stand to make the Effector in the right lenght, ALL of them. 29/3 New effector in now ready and the old is off the program. All the rest part for the effector. go to:https://www.thingiverse.com/thing:716253 14/4 I make all thev wire yesterday, Today is the day for a spinn. Try make a video to you. I had some problems with the carriage, the belt tension was not good enough, I has to make some kind of integraded belt tension in the carriage. I post a pic. of it. 26/4. Just got the Extruder finish, a Geared Greg Wade Belt Bowden extruder, 80 tooth and a bit bigger. I run the Bot and the nois from the Linear Bearing was enorm, so I change to the homemade IGUS and what a difference, I Work so perfect. I rty the Linear bearing to see if it Work, and it does, but the IGUS is lighter and run smoothe. 5/5 I make the new Extruder ready and it run with 1.75 and 3mm filament 5 bearings One integrated in the 80 Tooth belt wheels and no noise. I make some pic. for you. the fil will come up when I know it Work perfect. 28/5 The extruder is finealy finish. I was a hard one, but now it runs like a charm, it has interaded bearing inside the wheels, and you can use 1.75 or 3mm. I make a mounting bracked to be Mount on the side of the Bot. Pic. will come 29/5 with a new video of the hole Bot running. 29/5 I made the Heatbed plate in 4mm Alu to be cut on a Waterjet. You can cut it like you want or redesign it. Use the SKP. file for this. here you also can see the glass plate, alu heatbed, the heater and the insulation pad. I use insulation from a car. 16/6 The Extruder is ready incl. Mounthttp://www.thingiverse.com/thing:791325 Instructions I have make some thinking about using nema 23 and a 32 Bit board. I make the file for Nema 23 Mount to u. in some time. Instructions and link will come Right now I testprint and wait for Alu. 2060 and 16mm steel rod. I just got all the magnet in N50, super strong. Work on a Direct extruder...It`s so cool . 12/1. I Work on IGUS bearing http://www.thingiverse.com/thing:630545 Becourse of the waight of the steel bearing. I also Work on the Hall endstop, and how to Mount the magnet on the Carriage. 16/1. I working on a Carriage with integarded IGUS bearing. Try out the 20/60 extrution and they fit perect. Ramps Board plate with rubber mounted fan for optimal silence. 30/1 Alu. profile :http://www.motedis.com/shop/Slot-profiles/Profile-20-I-Type-slot-5/Profile-20x60-I-Type-slot-5::499.html Hotend : http://e3d-online.com/https://www.youtube.com/watch?v=_PQjwvWoGpk Steel Rod 16mm.http://www.dold-mechatronik.de/Praezisionswelle-16mm-h6-geschliffen-und-gehaertet-ZUSCHNITT. Cheap ABS. 920g. EU14.00http://www.3dplastx.com/abs-filament-spools.html 27/2 The Effector and the Carriage I made with a Heat support, you just take it off after printing. 2/3 Magnet countersink http://www.ebay.co.uk/itm/311149809703?_trksid=p2059210.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT Steel ball 12mm. http://www.ebay.co.uk/itm/161126780433?_trksid=p2059210.m2749.l2649&var=460220302029&ssPageName=STRK%3AMEBIDX%3AIT 5/3 IGUS Printed Bearinghttp://www.thingiverse.com/thing:630545. PS. Make em 20-30mm long and use 4-6 on every Carriage. Glue em on the Carriage, but allain it all on the Rod before you do so, use time on this one. I can make a video for u. 21/3 Orginal IGUS bearings. If you go for the orginal IGUS for this build.http://www.igus.eu/wpck/12157/Motek14_N14_6_3_Vollkunststofflager?playlistid=55 26/4. Hall Endstop. You can use thiese modelshttp://www.ebay.co.uk/itm/301177207873?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT. 1 Red led is on all time, at Home 2 Red led is on http://fabber-parts.de/shop/index.php?a=128 1 Green led on when the Bot is running, at home no light 5/5 Timing belt for the Extruderhttp://www.ebay.co.uk/itm/Rubber-Synchronous-belt-Transmission-belt-Stepper-motor-accessories-DIY-/181371266075?pt=LH_DefaultDomain_3&var=&hash=item2a3a91e41b. 19/5 Heatbed 220V 800W.http://www.aliexpress.com/item/Free-Shipping-3D-Printer-Heated-Bed-Siicone-Heater-Dia-400mm/1879833070.html

With this file you will be able to print Delta Bad Boy 3d printer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Delta Bad Boy 3d printer.