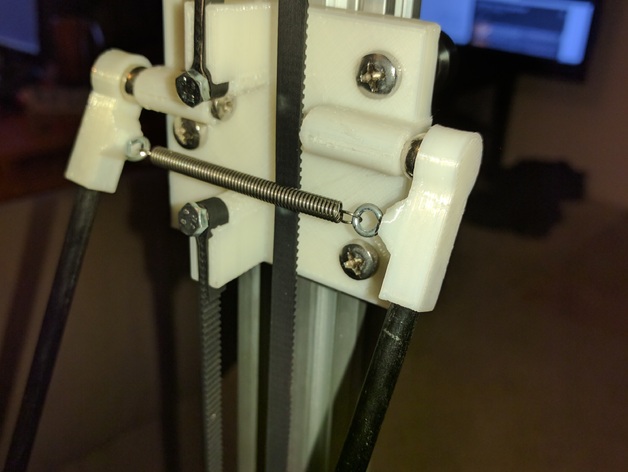

Delta effector system for 20x40 Vslot w/spring-ball joints

thingiverse

I was looking for a carriage design that didn't use magnets and would be easy to disassemble, but didn't find anything satisfactory, so I made this. The carriages use the openbuilds mini-v wheel kits and are designed to ride the wide face of 20x40 v-slot extrusion. The spring clipping arrangement was based on some photos I've seen of pick&place delta robots. For the whole assembly, print the following: 3x carriages (either V1 or V2) 1x effector 12x rodends When tightening the tapped ball bearings, wrap a cloth around the ball before gripping, to prevent scratching the surface. To fit the rod ends onto the rods, you should construct a jig to ensure they all have the same effective length. I drilled some holes in a plank and mounted 2 ball bearings there temporarily to hold the rod ends at a fixed distance when epoxying them in place. The fit of the mini-v wheels onto a 20x40 extrusion that I encountered was quite snug, but if yours comes out loose, a bent paperclip or some printed tensioner can be used to hold the free ends of the mini-v wheel shafts together. V1 is shown in the photos, but upon assembly I realized that the springs would rub against the belts. V2 has the belt mounted closer to the carriage plate and ball bearing mounts are up, out of the way. Longer bolts can be substituted for the M5x25mm ball bearing mounts, but the gap between mounting points should be increased to allow the longer bolts room to slide in. A full BOM includes the following: 12x M5x25mm machine screws (to mount ball bearings) 12x 10mm slotted, tapped ball bearings (found on ebay, I was told that these are normally used for some photography purpose) 6x arms of your choice, 6mm OD (shown: pull-truded carbon fiber from Goodwinds) 6x M3x10mm machine screws (for belt mounting) 9x openbuilds mini-v wheel kit (http://openbuildspartstore.com/delrin-mini-v-wheel-kit/) 12x eye hooks (~1.5mm shaft, found at hw store, open or closed loop will work) 6x 2in-2.5in extension springs (found at hw store, or mcmaster if all else fails) Print Settings Printer Brand: RepRap Printer: prusa mendel i2 Rafts: No Supports: No Resolution: .2 mm Infill: 40% Post-Printing Cleanup I encountered a great deal of difficulty getting clean holes from my old reprap, and I would suggest thoroughly drilling out the slots and holes before attempting assembly. The rod end cups should be cleaned up with a 10mm ball endmill.

With this file you will be able to print Delta effector system for 20x40 Vslot w/spring-ball joints with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Delta effector system for 20x40 Vslot w/spring-ball joints.