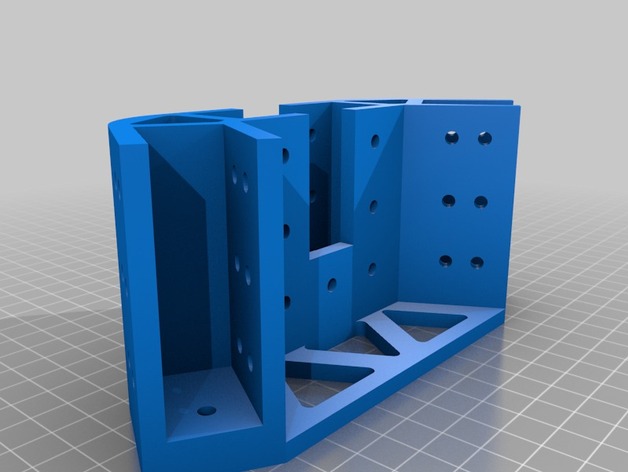

Delta One Frame

thingiverse

A very simple delta frame design using only 2060 extrusions and a single type of bracket! Hence the name Delta One. I plan to use this easy design to create my delta printer. A single Misumi 2060 is cheaper than using 3 x 2020, yet it is much stronger. The idea behind using 2060 is that it is overall more cost effective to achieve a very solid delta frame. Also this design does not disable the mounting versatility of the extrusions at each corners. Therefore, designing motors/idlers/rails/smooth rods brackets are all modular and open to different requirements. The bracket is split into 2 pieces for each legs so that even the smallest printers should be able to print it. Updated with design B. It is now symmetrical and bottom mounting holes are countersinked. Updated with design B1. Made the inner dimensions whole numbers. Fillet the outer corner. Updated with design C. Made a 1 piece design for larger printer. Updated with design D. Reduce materials. Instructions For half brackets, print a total of 12 brackets. Total number of 2060 extrusions needed: 3 x legs and 6 sides of whatever size you want. Typical sizes would be 1000mm legs and 300mm sides. Mounting holes are all 4mm. Print volume required: X-100mm Y-60mm Z-70mm. For full brackets, print a total of 6 brackets. Print volume required: X-160mm Y-60mm Z-70mm.

With this file you will be able to print Delta One Frame with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Delta One Frame.