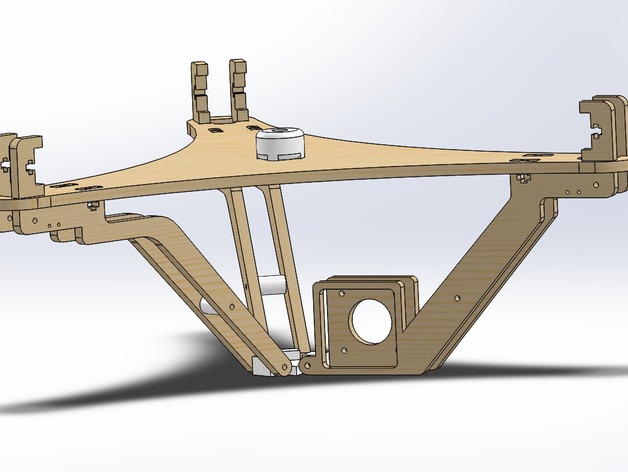

DeltaPrintr Extruder Relocation + Stiffening Brackets

thingiverse

I was extremely dissatisfied with the stock extruder setup (too much weight hanging over one corner) and fed up with tower wobble ruining the finish of my prints. Used factory sketches to design new brackets which locate the extruder underneath the top plate, but above the effector plate. This also eliminates about 100mm from the bowden tube, reducing friction and the chance of the extruder skipping. It has completely eliminated any tower wobble I've had while running prints up to 30mm/s, and movement speeds of 150mm/s. I created a filament guide/cleaner that fits into the top plate; you will need to use an external filament spool. Both .dxf and .stl files are included for the six main brackets - I highly recommend having these made from laser-cut 6mm ply (use hobby ply, or laser ply - not marine ply) however you could print if you have no other options. You will need: top bracket x4 extruder bracket x1 extruder bracket x1 filament guide/cleaner x1 (printed - flip upside down) middle bracket x1 (printed - lay flat) spacer x3 (optional) Screws needed are M3x30 x3 (or 6 if you use the spacers). Everything else uses the factory setup. Print Settings: Printer: Deltaprintr Rafts: No Supports: No Resolution: .15 Infill: 20 Notes: Stuff the filament cleaner with cotton pads or sponge, depending on what you prefer. A light squirt of machine oil makes the whole thing run much smoother. You will be able to cut approximately 100mm from the bowden tube.

With this file you will be able to print DeltaPrintr Extruder Relocation + Stiffening Brackets with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on DeltaPrintr Extruder Relocation + Stiffening Brackets.