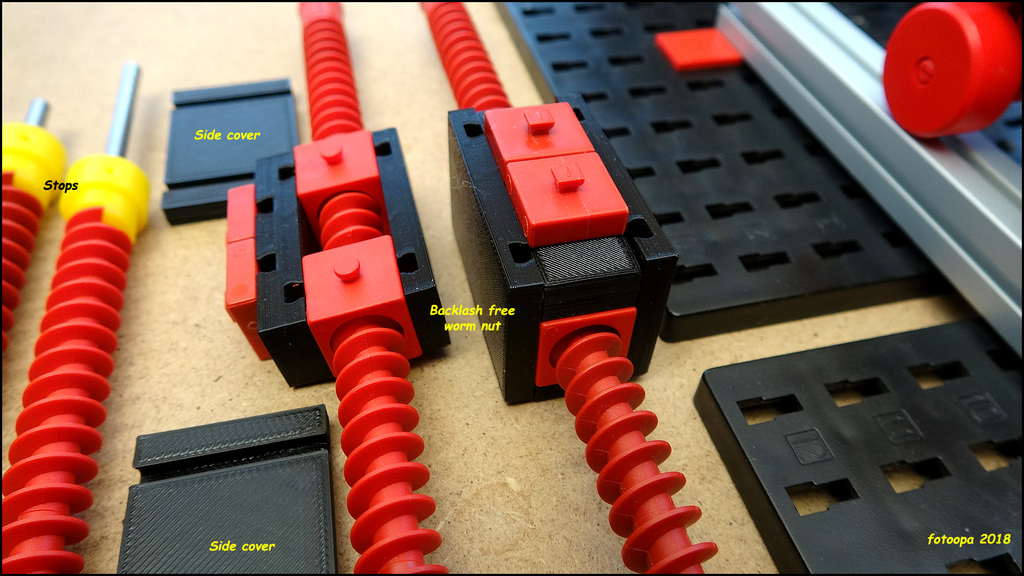

Designing a backlash-free drive with a worm screw.

thingiverse

Designing a backlash-free drive with a worm screw. To eliminate the backlash, 2 worm screws are required that have a small mutual shift. With only 1 worm screw you have about 0.6mm of play which is a lot. A custom housing now contains 2 worm screws at the right distance. These can easily be mounted on the standard base plate 120x60mm. In the setup I use shafts of 500mm length. To increase stability another 4 small support wheels are added that run on a flat surface. This way the car can not tilt and remains very stable. With an XM-motor and a gear reduction of 3 times the drive goes quite smoothly. At the end I made a worm screw stop (yellow plug). Also the gear of 30T contains an adjustment for the worm screw. In the foreground of the picture you see the details of the housing. I also made a quadrature decoder with home point with a ball bearing D8x4x3mm With an encoder disc with 15 neodymium magnets you get 60 pulses per tour or 0.0785 mm per pulse.

With this file you will be able to print Designing a backlash-free drive with a worm screw. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Designing a backlash-free drive with a worm screw..