Diamond Hotend Conversion, Anycubic Linear Plus Kossel Printer

thingiverse

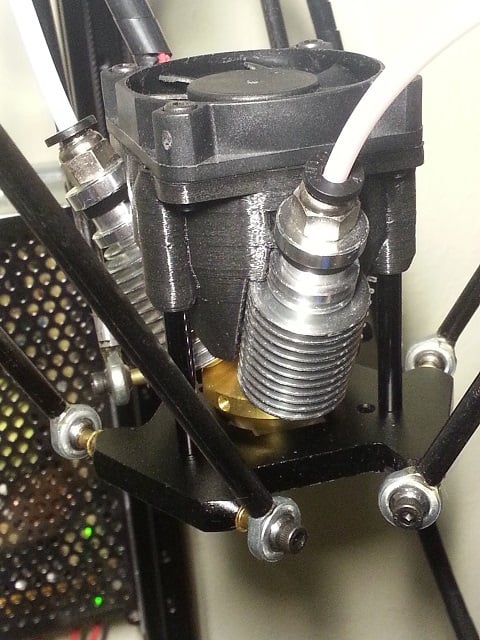

Parts for installing a 3-filament diamond hotend on a Anycubic Linear Plus Kossel 3D printer retain the original aluminum effector plate and arm geometry, increasing print height capability to about 315-318mm. The shroud is a remix of kharar's shroud modified for ease of routing wires and accessing the heating element and thermal probe. Elevated with aluminum standoffs for rigidity and heat tolerance, all printed components shown in photos were produced with this converted printer. Requires three 35mmL x 5mmOD, M3-threaded aluminum standoffs, noting the orientation and clearance between the hotend and effector plate. Drill the three holes in the effector plate to mount the standoffs. Six M3x15 socket head screws are needed for mounting the standoffs to the shroud and effector plate, and four for the 40mm/50mm fan to the shroud. The blower mount and ducted shroud have been revised with a flange that accommodates a 40mm fan. A clip-on nozzle model has also been added, allowing for easy tool-less removal for cleaning the nozzle and hotend tip. Two shroud versions are available: one with a short center cylinder for use with the bolt-on nozzle, and another with a tall center cylinder for use interchangeably with the clip-on nozzle. To ensure proper functionality, be sure to disable ENDSTOPS_ALWAYS_ON_DEFAULT in your printer settings. This will prevent Z-hop crashes and layer shifts that can occur when using Marlin 1.1.9. Additionally, consider switching to Makerbase MKS SERVO42 closed-loop steppers for quieter operation and increased precision. Updated models are available on Thingiverse, including a two- and three-color test model and a protective cage design for the motor. A small update has also been made to improve cable routing and address asymmetry issues in the original shroud.

With this file you will be able to print Diamond Hotend Conversion, Anycubic Linear Plus Kossel Printer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Diamond Hotend Conversion, Anycubic Linear Plus Kossel Printer.