DIP-Clip for In-Circuit Programming/Analyzing ICs

thingiverse

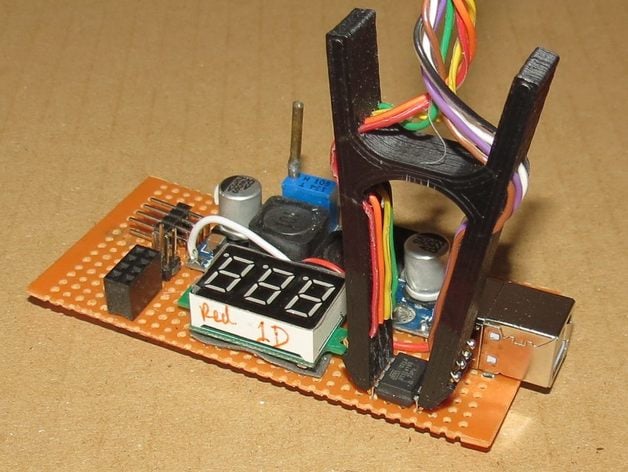

In my projects I often use microcontrollers which can be reprogrammed via ISP (in-circuit programming). If there is enough space, I usually intergrate a 6-pin ISP header, so that I can easily reload new firmware if required. However, sometimes, space is at a premium, which means I'll have to do without an ISP header. So the aim of this project was to generate a contact clip for in-circuit analyzing and programming of standard DIP ICs with 0.1" pin spacing, which allows me to reprogram microcontrollers and EEPROMs, and also debug my developments by analyzing the pin signals on the ICs directly. The pin contacts are made from standard pin headers. The bridge in the clip tweezers provides a spring to firmly clamp the contacts to the IC. Small gaps between the pins allow each pin arm to move individually, so that the contact force is spread to all pins evenly. The lead wires are fed from the inner rear of the clip through three holes to the outer front of the clip where they are soldered to the contacts headers. For printing, ABS is preferred in order for the plastic to provide the necessary elasticity. To allow printing despite of the (in printing position horizontal!) gaps between the pin arms, explicit supports are generated (shown red in the OpenScad drawing) which need to be cut away with a razor blade or a narrow knife after printing. As the arms should move freely against each other, sometimes it is necessary to "clean" the gaps with thin sandpaper. The holes for the pin headers and the wires are quite tight, so it may be necessary to cleanly redrill them after printing, for the pin header tips I got the best results with a 0.8mm drill bit. STL files for the standard 8-, 14-, 16-, 20- and 28-pin narrow DIP ICs as well as for 28- and 40-pin wide DIP ICs are provided. Other sizes can be easily obtained by modifying the fully parametrized SCAD file. Note that this project was not as easy to accomplish as I initially thought. The approach presented here is the result of several iterations, from first using simple wire loops, the switching to pin headers for the contacts and finally introducing the free swinging pin arms - the latter were definitely the key for getting good contacts on each pin every time... Instructions The Dip-Clips were printed from 3mm ABS filament on my DIY Prusa i3 using a 0.4mm nozzle with 0.56mm extrusion width and 0.252 layer height. I print on a clear mirror without Kapton tape but thoroughly cleaned with acetone and double concentrated lemon juice.

With this file you will be able to print DIP-Clip for In-Circuit Programming/Analyzing ICs with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on DIP-Clip for In-Circuit Programming/Analyzing ICs.