Direct Geared Belted Extruder 1,75mm

thingiverse

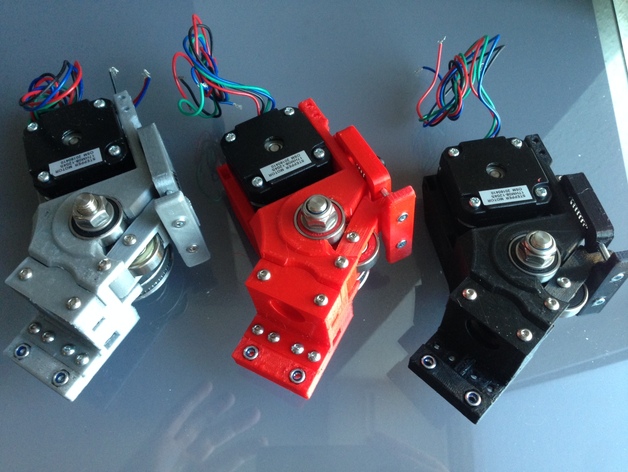

Direct Geared Belted Extruder 1,75mm (v1) This model has been superseeded for a V2. New model has been turned 90 degrees: Direct Geared Belted Extruder V2 (1,75mm) If you are looking for a bowden version, you should go see my Belted Extruder v.3 for 1.75 instead. Key features Compact highly accurate, easy to use and -install Direct Drive Geared Belted Extruder for all 1,75mm filaments. Gearings 1:3.75 Weight including motor: 316g - This is inclusive all gears, belt, screws, nuts etc.. Please note that a standard normal Nema 17 weights 290g in itself, so 316g is VERY light Only Quality items used to for Higher longelevity and Accuracy. No exotic, hard to find expensive parts used. Set and Forget Idler system - try it! :) Prusa compatible mount hole spacing. Silent running due to belt operation. Mount holes for Optional usage of Expansions. Expansions options Option to mount sensors or other expansion behind hotend. Cooling solution can be mounted on Expansion slots instead of on hotend Opton to mount cable management, Motor-cover, fans and other expansions next to motor. Nema 17 used I am using Nema 17 "pancake" as in flat model. Manufacturer Part Number: 17HM08-1204S 0.9deg Nema 17 Stepper Motor 1.2A 11Ncm/15.6oz.in 42x42x20mm I found it on german ebay. You can reuse whatever Nema 17 you might have, but using a smaller motor dramatically decreases the weight. Usage Requirment While this Direct-Drive Belted Extruder 1,75mm (v1) has standard hole mount spacing of 23mm center to center of the mount holes, you are going to do one of the following 3 options: Use a modified x-Carriage, which I'll provide soon. Remove 1-2mm of the top of your existing Carriage. Use a 8-9mm spacer-plate to put between your existing carriage and the extruder. Buy one? I am selling these. Also just the metal parts. Drop me a message if interested. I live in Denmark and can ship for DKkr 35 in Denmark, but let me know where you live, and we'll see. 3D model and files? I do not offer up the extruder in other fileformats than STL, but you can see the model on MyHub on Autodesk's servers. Print Settings Printer: My Crossbot design Rafts: No Supports: Yes Resolution: 0.2mm max Infill: 25% or more Notes: I have provided 2 models: 1 with support and 1 without for people who'd like to setup support on their own. Other Settings 3 Borders/Perimeters. 3 Top/Bottom -layers or more. I have printed in PLA and PETG without resize modifiers in slizer. If you use ABS you might need to enlarge your object in the slizer. Post-Printing Remove supports colored red here. Remove supports colored red here. How I Designed This I used Autodesk Fision 360 There is a common misconception that Autodesk Fusion 360 costs money, but it truely is totally free to use for private people and small businesses and not just students and teachers. Once installe you are asked to accept the licens and just put in you are private person or small business as appropriate. Once a year you have to re-accept the licens. Also check out their free app for phones and tablets which can be used to view and share your items. BOM Bill Of Materials 60GT-2 Pulley 16GT-2 or 20GT-2 Pulley. E3D Hobbed Bolt - Hobb-Goblin-8mm-Shaft. 172-GT2 Belt. 0-1x m6 Push-Fitting for 1.75mm filament. 2x 20mm steel springs. 1-1.2mm thick. 3x 608 bearings. 8x22x7 - Type doesn't matter. Various m3 nuts, screws and spacers - Details below Detailed Screwn/Nut BOM 13-17x M3 nuts (if using cable management or motor-covers) 4x m3 spacers - Fasten Motor 4x m3 8mm - Expansions bar. 4x m3 10mm - Fasten Motor. 3x m3 16mm - Hotend Fastener and Idler. 2x m3 25mm - Idler and Spring Frame joints. 2x m3 50mm - Socket Head Screws, Partially Threaded. 4x m4 - Lock-nuts Addons Everything for my Belted Extruders, including Mounting brackets can be found in the my Collection: Belted Extruders by Dintid Addons are trickling in, so hit follow or just check back now and then :) Insert m3 nuts into the Insert Screw in the m3 50mm screws untill they are flush with the bottom of the Mounting hole measurements. Extensions-plate and holespacing measurements. Distance measurements to build Extensions and Fan-Shrouds etc. Metal parts-pack - Please note that there are extras of the smallest sizes to make up for any accidents. Calibrate Steps/mm A few stepper examples. Remember to do a proper measurement yourself. I have rounded the numbers up/down. When using: 16-GT2 + 60-GT2 pulleys + 1/32 multistepping + 0.9degree motor = 2050 steps/mm 16-GT2 + 60-GT2 pulleys + 1/16 multistepping + 0.9 degree motor = 1025 steps/mm 16-GT2 + 60-GT2 pulleys + 1/32 multistepping + 1.8 degree motor = 1025 steps/mm 16-GT2 + 60-GT2 pulleys + 1/16 multistepping + 1.8 degree motor = 510 steps/mm

With this file you will be able to print Direct Geared Belted Extruder 1,75mm with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Direct Geared Belted Extruder 1,75mm.