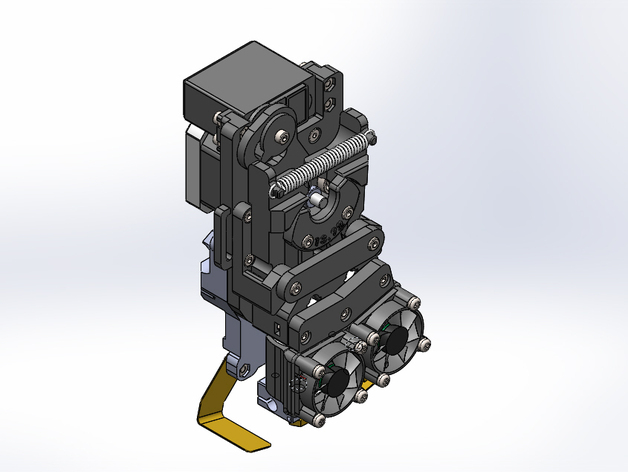

Dondolo v1.01b

thingiverse

Dual rocking extruder for Prusa i3. Direct extrusion with a single stepper motor. Basculating heads prevent inactive nozzle to interfere with the part already printed avoiding contamination. Anti-oozing system. Reduced mass allow direct extrusion. 09/05/2016 In order to make the project more "readable" I tried to simplify and put in some order. i) Eliminated the 3mm version (too hard to make it working!) ii) Added 0.5mm clearance from heatsink to backplate, so modified Idlers, Idlers_pivot and Pendulum. iii) Modified Idlers to avoid mutual interference and Servo_Cam interference iv) Modified the fan duct (print fan) for a more efficient cooling v) Added "mouse ears" to Pendulum and BackPlate to improove adesion and make prints easier ( if you don't want them you can do a "Divide ojects" and remove). 24/03/2016 Dual Dondolo on CoreGF: automatic head changehttps://youtu.be/E3vc4A_5x28 05/12/2015 Published the "DONDOLO v1 Assembly Guide rev_10.pdf" to help during the assembly procedure. Published the "PTFE Cutting Tool" to help cutting the PTFE tube in the proper way. 13/10/2015 Added a driving wheel spacer fo use with E3D MK8 type driving wheel. Insert the driving wheel in reverted position, ( the grub screw outside ). Firmware configuration tool available at: http://marlinkimbra.it/ thanks to MagoKimbra (Alberto Cotronei). No more need to manually adapt the fw, you can configure and dowload an advanced version of Marlin supporting Dondolo (among other interesting multicolor extruders like "4 Way Flux Capacitor":http://www.thingiverse.com/thing:498922) BOM in the instructions. Note: the Cam _Pendulum is the part you have to "tune" depending on your filament diameter and drive gear effective diameter. Here is for 3mm filament and a 7mm drive gear (made hobbing a 8mm round bar). 19/May/2015 Is ready the version for E3D v6 1.75mm filament hotends: Pendulum_E3Dv6_175.stl Cam_Pendulum_175.stl Tested Mk8 E3D drive gear,... very good drive gear, I strongly reccomend it. Also added a "front bar" to increase the stiffness of assembly. Thank you. :-) First test:http://youtu.be/gPh625bMtUg Anti-oozing test:http://youtu.be/gTiOnj0SXrU Change Log: Ver. 1.02 Changed the hotend dual fan duct from 25mm to 30mm (4 CFM) Ver. 1.01r updated Cam Pendulum (Cam_Pendulum_101r.stl) the older was'nt enough to keep the clearance of the inactive filament from drive gear (for 3mm filament). Ver. 1.01 minor changes on : pendulum to increase stiffness and idlers and pendulum cam to increase pression from spring to filament and stability on bistable system. Instructions Print preferably in PETG, more elastic and durable material than ABS and easier to print. Layer 0.2, T 240°C, bed 50°C, speed 45-60mm/s. Follow "DONDOLO v1 Assembly Guide rev_10.pdf". Soon a wiring diagram. DONDOLO v1.0b bill of materials. Screws and nuts 2 3.5mm washer 22 M3 nuts 4 M3 x 8mm countersunk socket screw (Motor) 2 M3 x 6mm socket head cap screw (Anti-oozing thin plates) 3 M3 x 8mm socket head cap screw (1 Servo Cam + 2 Prints Fan Duct Support ) 6 M3 x 10mm socket head cap screw (3 Double Clamp + 2 Idler Pivot + 1 BackPlate) 4 M3 x 12mm socket head cap screw (Servo) 6 M3 x 16mm socket head cap screw (2 Cam Pend. + 2 Backplate + 2 Prints Fan) 4 M3 x 25mm socket head cap screw (2 Front Bar + 2 Prints Fan) 2 M3 x 15mm Spacer (X Carriage - Prints Fan Duct Support) Mechanical parts 1 E3D MK8 Filament drive gear 1 F 695ZZ ball bearing 2 604ZZ ball bearings 1 6mm x 52mm x 1mm traction spring Electrical parts 1 standard servo (metal gears MG995) 1 NEMA 17 stepper motor 42BYGHW208 (or 17HS13-0404S) 0,4A 30ohm 37mH 1 5v DC-DC converter 1 40mm fan Plastic printed parts (0,6EU cm^3) 1 Backplate 1 Pendulum 1 Pendulum Cam 1 Idler sx 1 Idler dx 1 Idler pivot sx 1 Idler pivot dx 1 Double hotend clamp 1 Double hotend fan duct 1 Servo Cam 1 Front bar 1 Prusa i3 X Carriage modified 1 Prints Fan Duct 1 Prints Fan Duct Support 1 Driving Wheel Spacer Custom parts 1 anti-oozing sx 0.5mm thin plate 1 anti-oozing dx 0.5mm thin plate 2 M4 x 7mm threaded rod Hotends 2 E3D v6 (or E3D Lite) Full Kit Note: the Cam _Pendulum is the part you have to "tune" depending on your filament diameter and drive gear effective diameter. Th recomended choice is the 1.75mm version with E3D Lite Hotends and E3D drive gear.

With this file you will be able to print Dondolo v1.01b with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Dondolo v1.01b.