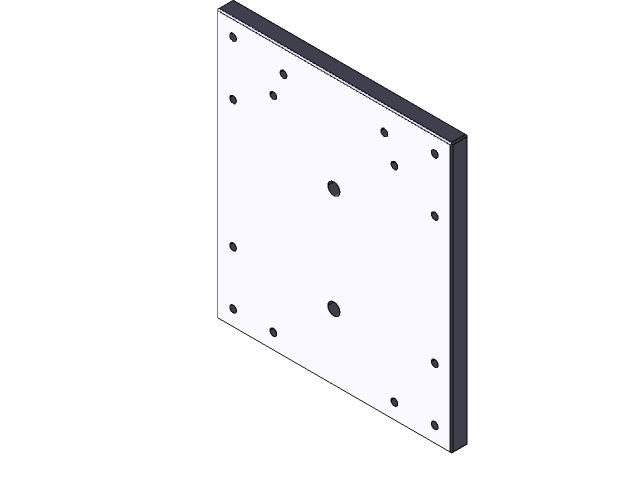

Drill Jig Design

grabcad

Designing a comprehensive drill jig requires meticulous attention to detail and a thorough understanding of manufacturing processes. Engineers typically start by specifying the dimensions and material requirements for the jig's framework, which should be robust enough to withstand the forces involved in drilling operations. To ensure accurate hole placement, designers incorporate precision-cut guides into the jig's design, often utilizing advanced CAD software to simulate the drilling process. These guides are typically machined from high-precision materials such as stainless steel or aluminum alloys, providing a smooth, stable surface for drill bits to engage with. The jig's framework is usually constructed from a durable material like steel or aluminum, allowing it to withstand the rigors of repeated use and handling. Engineers may also incorporate features such as adjustable stops or calibrated measuring systems to ensure precise alignment and positioning of the drill bit. In addition to its functional components, the design of a complete drill jig should also prioritize ergonomics and user safety. This includes incorporating features like easy-to-use controls, secure storage compartments for tools and accessories, and clear labeling or markings to facilitate navigation during operation. By carefully balancing these factors, engineers can create a highly effective drill jig that streamlines production processes while minimizing errors and ensuring high-quality results.

With this file you will be able to print Drill Jig Design with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Drill Jig Design.