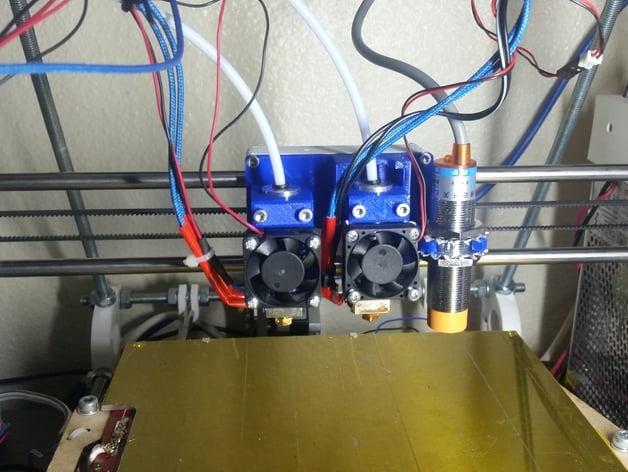

Dual E3D Mount for Mono Mendel

thingiverse

Printer no longer owned. Unsupported as of Feb 2017 This dual E3D v6 mount attaches to the Mono Mendel carriage from RepRapPro. I have included my CAD files so that you can adapt it to your mounting carriage if need be. Because the new mount has a prox sensor, I am able to use the spring that is normally used for adjusting the Z axis calibration for the E2 height adjustment. The difference between v2 and v3 is which hotend is adjustable. In v2 it is the right and v3 the left. BOM: x9 M3x25mm x9 M3 Hex Nuts x1 Spring x2 E3D v6-Bowden: http://amzn.com/B00NAK9L6Q x1 18mm Prox Sensor: http://amzn.com/B005HKXKOG x1 Dual E3D Mendel Mount with Prox Sensor v2 or v3 x1 ADJ Collar Mount x2 Collar Mount Assembly: Complete post-processing Add hex nuts Assemble ADJ collar mount Mount to carriage Mount E1 in fixed collar Mount E2 in adj collar Mount 18mm prox sensorAssembly instructions bellow Software: I use Marlin with auto bed leveling. The nozzles are 37.9mm apart in v2 The nozzles are 34.9mm apart in v3 My actual offsets were about 1mm off from the CAD values so they will take some tweaking to get right. The prox sensor is offset by X:30 Y:11 in v2 The prox sensor is offset by X:28 Y:11 in v3 Be sure to adjust your Z offset on the fixed hotend before leveling the nozzles. I have my switch retraction amount at 14 and it has been working well for me. This amount should be just enough so that you get the least amount of oozing. Anything too much can product clogging. Actual offset may vary Nozzle offset calibration: When calibrating the nozzle offset, I used this thing: http://www.thingiverse.com/thing:401570 as well as this thing: http://www.thingiverse.com/thing:124450 The first file i used to calibrate the offset in the X and Y directions. These settings are put into your slicer (I use Cura). See featured picture above of my test results. When plating in Cura, the outer wall was the part printed with E2. Therefore adjustments were made to its placement relative to the center square. The adjustments are made based on the center square location relative to the walls. Follow these rules when calibrating: Square is too far right-> make your offset value more negative Square is too far left-> make your offset value more positive Square is too far down-> make your offset value more positive Square is too far up-> make your offset value more negative My offset values started at X:-37.9 Y:0. My first print has the square down and to the right. As I dialed in my calibration, my values eventually settled at X:-38.93 Y:0.82. I have not tested these rules with v3, but I imagine they will simply be opposites fro the X calibration and the same for the Y calibration. The second file is used to calibrate the overlap setting (found in your slicer), which is the amount the perimeters are overlapped. A good setting will have the walls touching enough to fuse together, but not too much that it overlaps a lot. Print Settings Printer Brand: RepRap Printer: Mendel Rafts: No Supports: No Resolution: 127 microns Infill: 20% Notes: This is a very fine layer resolution that I know my printer can achieve. 150 microns should work as well. The build material is PLA; however, all other materials should work just as well. Post-Printing After printing, you will need to remove and supports and add in the M3 hex nuts before assembling. Remove support tabs from ADJ collar. Assembly Hex nut installation The first part of assembly is to add in all the hex nuts. Follow the placements shown bellow as well as the installation instructions for the fixed collar mount hex nuts. Hex nuts go in on either side of the ADJ collar mount. Use pliers to install these hex nuts. Keep in mind that some hex nut holes that were bridged will need to be cleared out or widened to fit the nut. ADJ Collar Mount Installation Insert your leveling bolt and sprint. My spring was in use so it is not in the picture, but it goes between the top of the ADJ collar mount housing and the ADJ collar mount as seen in the featured photo at the top. After insuring the glides and rails are clear of material, slide the ADJ collar mount onto the rails. Use the leveling bolt to raise the ADJ collar mount to above the fixed collar mount. Hex nut installation ADJ collar mount installation Mounting to Mendel Use four M3x25mm bolts and M3 hex nuts to mount the assembly to the Mendel carriage.

With this file you will be able to print Dual E3D Mount for Mono Mendel with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Dual E3D Mount for Mono Mendel.