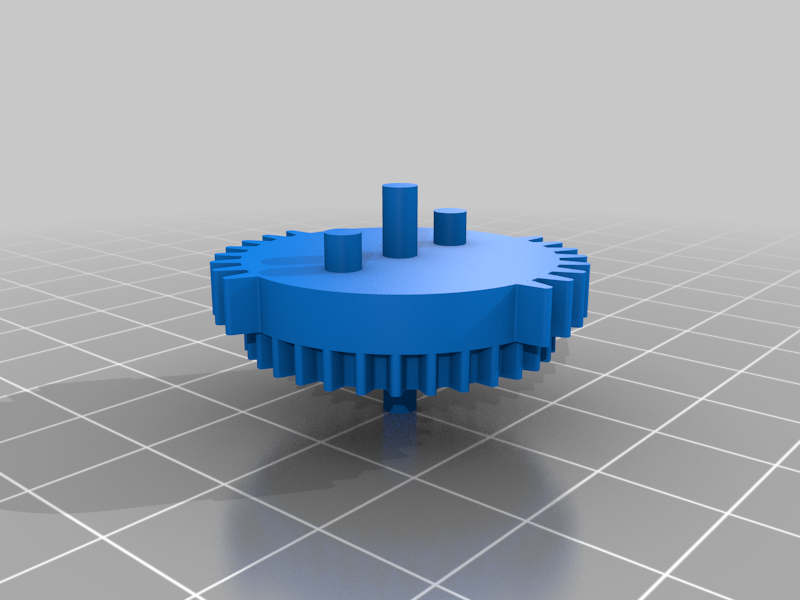

Dual Sector Gear Airsoft/Gel Blaster AEG

thingiverse

Preface ====== Decided it would be a bad idea (in the best way) to make a plastic Dual Sector Gear (DSG) for my gel blaster because why not? Anyway, this is by no means practical and you only get 2-3 mags though I printed it in PLA so If you clean up the teeth so they're a little tougher and printed on 0.1mm or 0.15mm layers with Nylon or PETG you might be able to get a whole game if you shim right. I included 4 STL files, - DSG Full Model is the entire rough model I made with center shaft and sector pins (you can't practically print this - DSG No Pins or Shaft is the DSG gear with a hole in the center so you can put your own shaft in and holes to glue in the sector pins - Sector Pin is a pin that can be glued into holes on the gear with no shaft or pins - Gear Pin is for if you're a nutcase and want to try using a plastic pin for the shaft (you'll need to print two and glue them in) Here's a terrible video of it 'working', I did get it shooting but got too excited and didn't film it then was too lazy to rebuild it and print another gear just to film it again. https://youtu.be/eFeFQ8KOFPA Instructions: ========== This is by no means a guide to making a working 3d printed DSG but just what I did to ghetto it together to get 2-3 mags before stripping the gear. 1. Print 'DSG No Shaft or Pins.stl' with the big gears on the bottom (I used 0.2mm layer height but I'd suggest 0.1mm) 2. Print 2 x 'Sector Pin.stl' 3. Push the metal shaft out of another plastic gear (takes a bit of force but should come out with a bit of effort), I used another broken sector gear 4. Press the metal shaft into the DSG you printed till you get a roughly even amount of shaft out either end (like a normal sector gear) 5. Glue the two sector pins you printed earlier into the sector pin holes using super glue 6. Since the design doesn't include nubs to space/shim the gear I just put a put a spare bushing onto either end (this is in addition to the ones already in the gearbox), I'd suggest shimming it after this so it sits right but if you're lazy like me just stack shims on top till the gear is pressed down tightly onto the gear below it (I forgot what it's called, the middle one) 7. Build the gearbox, cut the tappet plate and pray it doesn't instantly explode I'd suggest PETG or Nylon and 0.1mm layer height as mentioned earlier but I used PLA and 0.2mm and got 2-3 mags (of about 100 balls per mag) but your mileage will vary. It was the first DSG build I'd ever done and I ghetto hacked the stock tappet plate down to size and used a 100 or 110 spring (whatever I had lying around too lazy to measure it) and stock tappet spring and managed to get it shooting at about 35rps 100fps after blowing up 2 or 3 gears which was enough for me so I stopped after that point but have fun and use a gun that's easy to pull apart and put back together because you'll be doing it a lot. I also included the fusion360 file if you want to work on it. Let me know how it goes I'd love to see a video!

With this file you will be able to print Dual Sector Gear Airsoft/Gel Blaster AEG with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Dual Sector Gear Airsoft/Gel Blaster AEG.