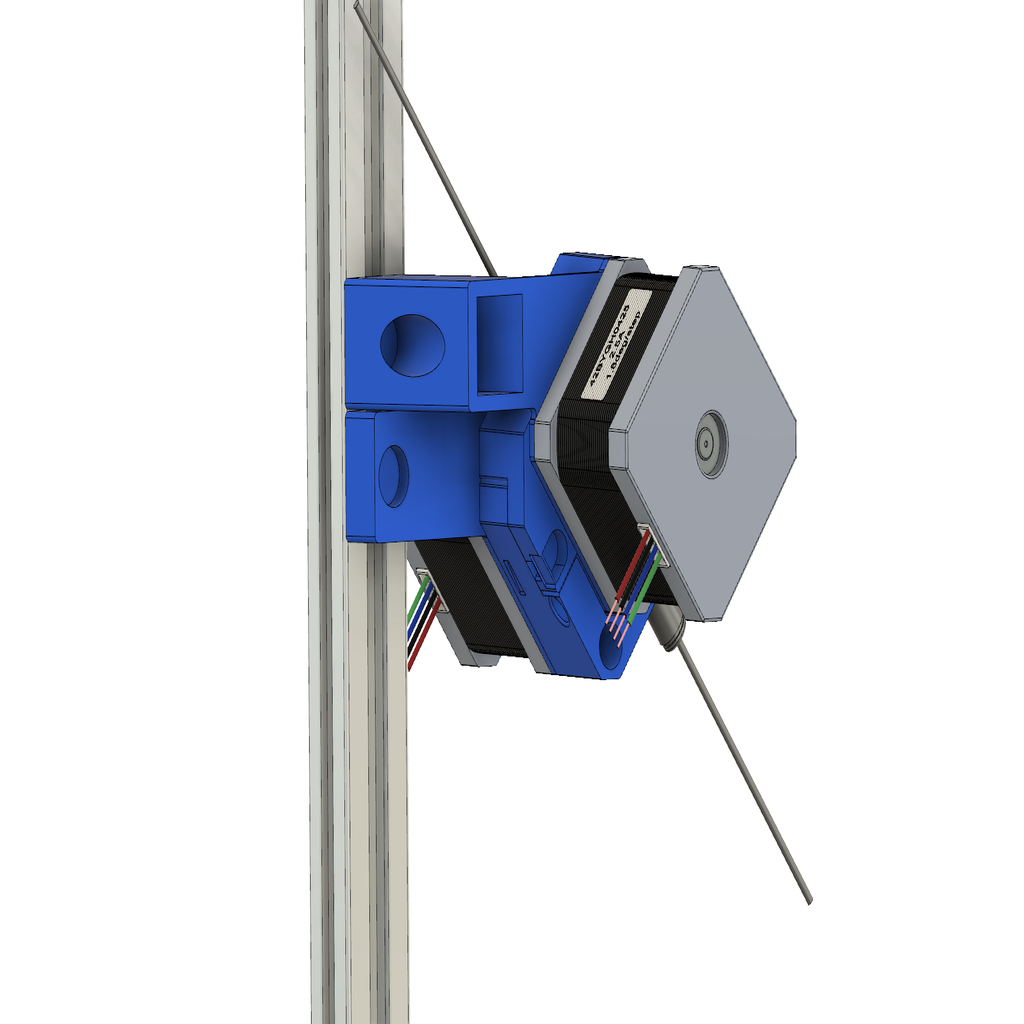

Dual stepper MK8 gear direct drive bowden extruder

thingiverse

Having dual steppers driving an extruder allows to use 0.9 deg/step motors for more accuracy or 1.8 deg/step steppers for increased torque. Largest benefit is gained if used with a dedicated stepper driver instead of connecting the steppers in series or parallel to one stepper driver. Additional parts needed: - 2x MK8 drive gears - 2x 625 sized bearings for filament guiding - 8x M3x12 DIN 912 screws for mounting to stepper motors - 4x M3 nuts - 2x M3x16 DIN 912 screws for fixing the extruder halves together - 2x M3x10 DIN 912 screws for adjusting drive gear pressure against the filament - 2x M3x12 DIN 912 screws for holding the bearings in place - 2x M3 washer for holding the bearings in place - 2x pneumatic push-in fittings with M5 threads for the bowden tube diameter in use

With this file you will be able to print Dual stepper MK8 gear direct drive bowden extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Dual stepper MK8 gear direct drive bowden extruder.