Duplicator 4/4x Hotend Upgrade Kit

thingiverse

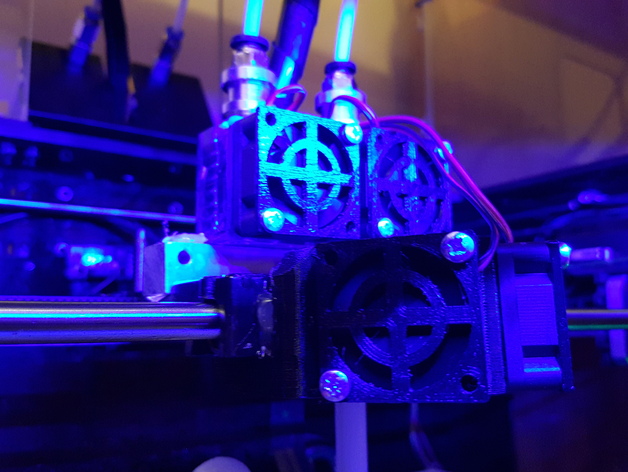

This is everything you need to upgrade your duplicator 4/4x into a hotend printer. This lets you lift off weight from the printing head and makes it easier for you to print faster and reduce wear on your printer. Parts to buy: - 2 x 24-volt E3D or equivalent hotends. I used imported ones I bought online, but my old heaters and thermocouples didn't work with them. - Kit must include heat sinks, fans, fan mounts, a 2mm ID pipe, push fits, and the head end. - 2x M6 x 30mm nozzle throats. Don't get rid of your old ones because you'll need them for the stepper motors (you can see in the picture where there's a thread going right up to the gear and bearing). Get longer ones since the hotends need extra threading. - If you could adjust the bed further, you might not need them. - 2 x Aluminum extruder Mk8 upgrade kits (left and right type). This is a great upgrade anyway, but it helps when attaching the hotend pipe to the stepper motor extruders. - A gear upgrade - this is one of the best gears you can use as others might squeeze too much on the filament. - 2 x M6 couplers. Screw in your old nozzle throat up to the extruder gear and bearing then screw on the M6 coupler and add a push fit (you can see in the picture). - 2 x 30mm 24Volt fans - these are for the cooling duct. - An M3 to 25-30mm screw - this is for the head stop plate. Parts needed for printing: - A head stop. This stops the stepper motors from falling off (you can see in the picture). - A Remote extruder mount - This lets you move the motors to the back of your printer. - A Hotend Cable Mount - Holds cables in place at the head end. Your old cable mount is now redundant. - Fan guards (2-4). They help save money because the fans can break easily. The hotends do need a cooling duct, which you glue into place using some hot glue. You must change the head moving speed to 150mm/s on travel and retract about 3mm. Don't make more than this, as this won't help at all.

With this file you will be able to print Duplicator 4/4x Hotend Upgrade Kit with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Duplicator 4/4x Hotend Upgrade Kit.