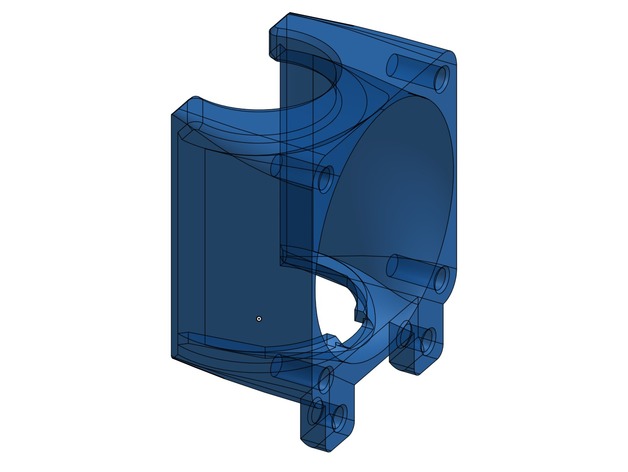

E3Dv6 fan duct for dc42 IR height sensor V1

thingiverse

A combination fan duct and dc42 IR height sensor mount, compatible with both original and new style heater block + silicone sock from E3D. The primary goal is absolute minimal z-axis and rotational movement relative to the E3Dv6 Heatsink, achieved through inherent firm rotational and vertical clamping pressure. Improvement potential lies in incorporating a method to mechanically secure the duct to an E3Dv6 heatsink in rotation, possibly by way of a locking grub-screw or other clamp arrangement. This part is freely available for further derivation directly in Onshape - links are available in the section 'How I Designed This', below. Feedback here or in Onshape is greatly appreciated. Print Settings: Printer: Wiener90 Rafts: No Supports: No Resolution: 0.5mm nozzle, 0.3mm layer height, x1 (0.42mm) perimeter Infill: 35% Notes: Designed to be printed with the duct inlet face flat to the print bed. I found that when printed at 50mm/s (compared to 30mm/s), the internal corner geometry is created 'slightly mis-formed', and this noticeably improves the part's grip on an E3Dv6 Heatsink - especially rotational grip. Z-position grip on the Heatsink appears to be equally good independent of print speed. This isn't ideal from a design perspective, but there you go - it is V1. Please leave any print-experience feedback in the comments and I'll consider tweaking the geometry. Post-Printing: Zero or very minimal cleanup was the goal. Please post any contrary experience in the comments. All the holes have small chamfers to offset the tendency of the fixing screws pulling material out of the holes. To prevent a gap forming between fan and duct during assembly, it is best to rest the duct with its exit side flat on a bench while screwing the fan to the duct and applying positive pressure to both through the screwdriver. The Sensor PCB can be mounted on either side of the tabs; I've yet to gain any experience to suggest a more favorable side of the tabs. Currently, I have mine mounted on the inside of the tabs, to place it as close as possible to the nozzle. Electrical-short protection is provided by Kapton tape applied over the rear of the PCB prior to assembly and additionally by the E3D silicon sock over the heater block. Furthermore, on my printer - any significant rotation that might cause a short is prevented by the proximity of the duct and fan to the X-axis bearings. How I Designed This: Designed in Onshape - post-processed in MoI3D Currently, Onshape doesn't have the capability to create the variable radius fillets visible along each of the four curved external edges of this part. To create those, the part V0 was exported as an STP file and the variable radius fillet details were added using MoI3D. Finally, the dumb solid was re-uploaded to Onshape as part V1. The closest workaround to the variable radius fillet problem I came up with is the part B1 - for reference only. Background and Inspiration: To attach the dc42 IR height sensor (v1.1) on my latest RepRap printer, I started out using a Mini differential IR / E3D V6 stock fan mount - by maczero. I like the simplicity of that mount, but unfortunately it created more issues than it solved. The stock E3D supplied 30mm heatsink fan was made a little noisier than without the mount fitted - possibly due to it affecting the fan inlet flow. It moved the height sensor far enough away (laterally) from the extruder nozzle that the dc42 supplied 3-pin power and signal connector collided with my printer's RH Z-shaft; a DC42 Mini height sensor board support for e3d v6 - by simon0362 may have addressed that issue by placing the sensor PCB closer to the hotend, however both mounts were ultimately affected by the third issue. The original E3D-v6 Fan Duct - by joshuarowley42 didn't grip the Heatsink firmly enough to prevent Z-movement of anything hung off it - primarily due to the requirement for a draft angle on the walls of injection moulded parts. The Fan duct and Mini Differential IR sensor v1.1 mount for E3Dv6 hot end on Kossel - by dc42 wasn't an option either, due to the physical constraints of my X-carriage and extruder.

With this file you will be able to print E3Dv6 fan duct for dc42 IR height sensor V1 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on E3Dv6 fan duct for dc42 IR height sensor V1.