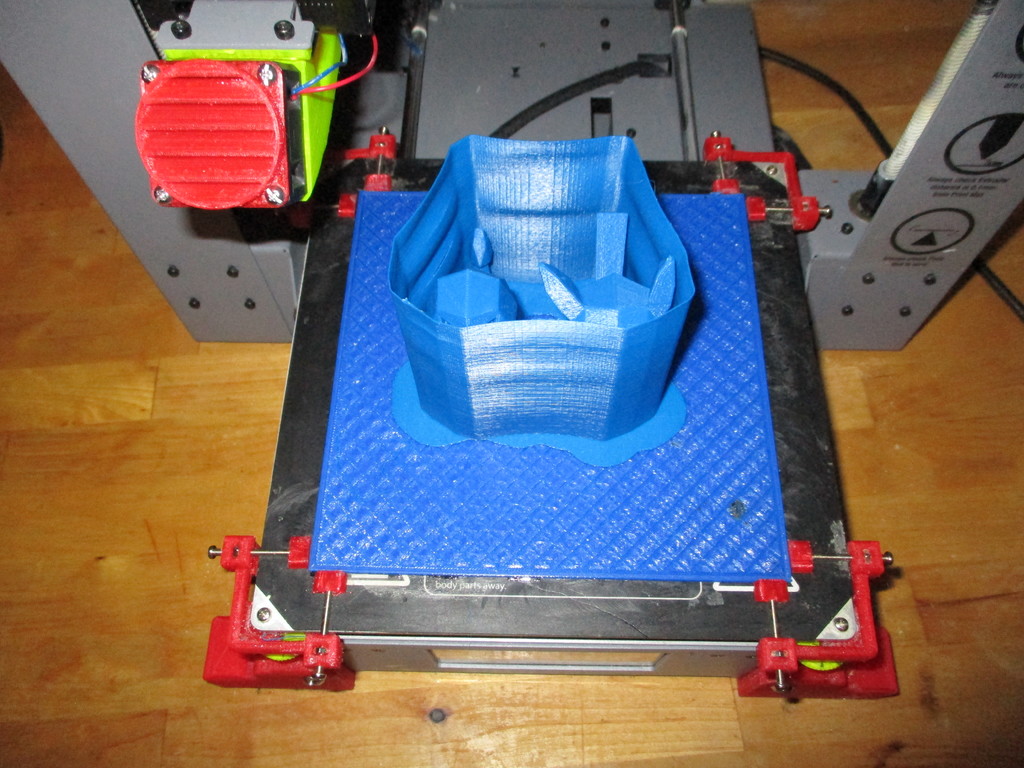

Easy ABS Print Base

thingiverse

Tired of failing ABS prints, I decided to set about finding a way to ensure a 100% (or as close as possible) way of ensuring ABS bed adhesion. Inspired by a number of half ideas from videos from Makers Muse and the 3d Printing Nerd I combined the concept of using another material (PETG) as a go between and a diamond surface to be filled by over-extrusion on the first layer - The end result was a design that suffered no failure and incurred very little damage from print to print. To make this base you will need a printer with the ability to print PETG, double-sided tape (I used thin double-sided sellotape from my local IGA but any good hardware store should stock some) and a means to stop side drift. Notes and Warnings..... - ABS was printed at 240, made use of a headed bed of 90c, used a raft and draft shield, please do not try cold printing as it will just peel away. - ABS and PETG at 90c make one hell of a bond!!!! on a failed print (broken filament...) I made the mistake of trying to remove the print straight away, this led to the base warping - it's best to wait until the temp reaches 50c before using a scraper to separate. Happy Printing!

With this file you will be able to print Easy ABS Print Base with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Easy ABS Print Base.