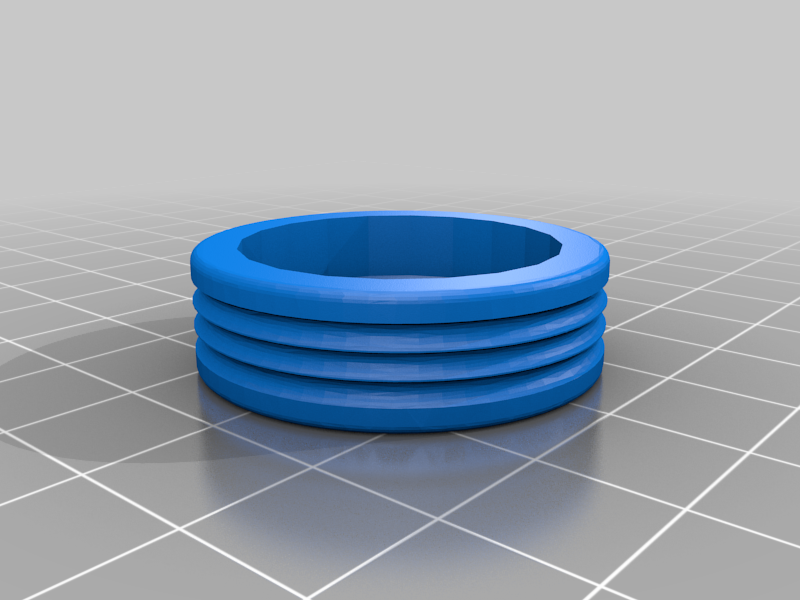

Elna Air Electronic Motor Friction Pulley

thingiverse

My wife has 3 Elnas from the 1980's. One is an Air Electronic Model 69 which uses a friction pulley instead of a belt drive on her 500 (Jubilee) and Carina. Recently, the machine slowed down and then stopped sewing. On inspection, the rubber tire on the wheel had hardened and no longer provided the necessary friction to transfer motor power to the driveshaft. Sanding didn't help. Looked into the cost to replace it with an aftermarket pulley but it was more than I wanted to sink into a spare machine. With some experimentation and inspiration from others that had 3D printed the cone shaped pulleys for older Elnas employing rubber O rings, I designed a replacement in January. It involves removing the rubber tire from the metal pulley such that the original bronze bushing is retained. A pair of needle nose pliers easily did the trick. The friction is provided by 3 - 28mm x 2mm rubber O rings which are inexpensive and can be easily replaced if need be without removing the pulley. So far, it has been working without a hitch. The pulley is rotated 180 degrees to fit into the 3D printed outer ring. This results in maximum contact of the 3 O rings with the flywheel and motor drivel. Sanding the residual rubber from the pulley after removing the tire afforded a good friction fit.without using adhesive glue but could be if needed. Some sanding of the outer edges may be necessary to prevent any rubbing. After reassembly, slowly operate the machine to ensure the pulley runs smoothly.

With this file you will be able to print Elna Air Electronic Motor Friction Pulley with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Elna Air Electronic Motor Friction Pulley.