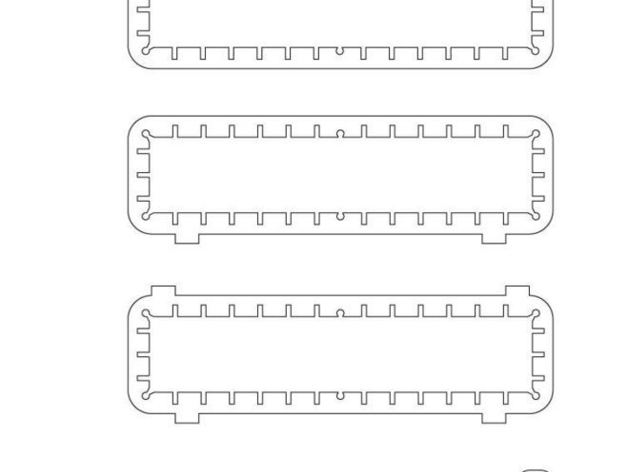

Enclosure Profiles

thingiverse

This project showcases Enclosure Profiles, a simple yet innovative way of designing attractive custom enclosures for electronic or mechanical projects using fabbers. Inspired by classic radio and electronics enclosure designs, these profiles feature inner-surface slots for easy slide-in mounting of circuit boards and chassis plates. Faceplates can be made from any flat stock material with openings for controls and displays. Different perimeter shapes add features like heat sink fins or stand-off legs. By combining variants, an infinite variety of enclosures is possible. This experimental design demonstrates a fanless low-power PC enclosure using 170mm square Mini-ITX motherboard dimensions, with faceplate templates provided. Users can modify the 2D outlines to create custom shapes and share their designs on Thingverse. Please adjust for specific hardware requirements and experiment freely.

With this file you will be able to print Enclosure Profiles with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Enclosure Profiles.