Encoders

thingiverse

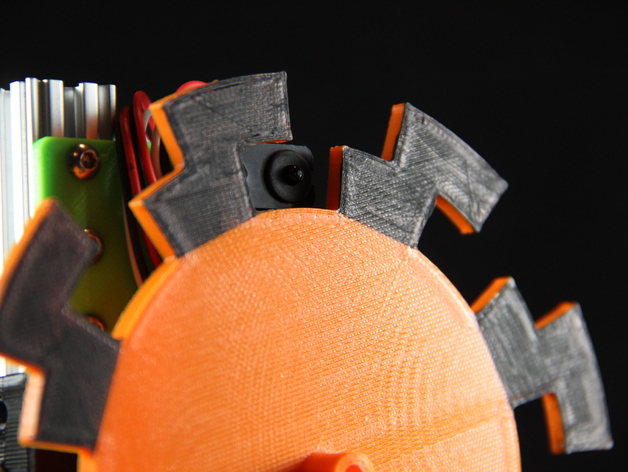

Let's build and explore how encoders work. We made three types of encoders. The incremental encoder measures the number of rotations a device completes. The quadrature encoder tracks rotations and direction. The absolute encoder can tell what degree the device is at. You might need to paint your encoder if the IR signal is transmitted through your print. How encoders work: https://youtu.be/j8rG3bjqriI General overview of our build: https://youtu.be/LjY1PSd8w2E You should try altering the encoders to have more steps and layers (bits), which will increase your accuracy. The code for these encoders can be found on our GitHub https://github.com/SciJoy/Encoder_Physics_Position. We used Adafruit break beam sensors along with these printed encoders (https://www.adafruit.com/products/2167). We used OpenBeam, but it is by no means required for this project. We created mounts for the break beam transmitters and receivers. We glued these sensors on and then screwed them on the OpenBeam. We also make motor mounts that attached to our OpenBeam structure. We'd love to see what you do with these encoders. You can send us messages on Twitter or Tumblr. Keep exploring. Post-Printing Printing the Absolute Encoder The break beams and the absolute encoder. Quadrature Encoder on OpenBeam This video explains how the encoders work. Overview and Background Project Overview Encoders are like Fitbits for motors. Depending on the type of encoder, they can keep track of the distance the motor traveled, the direction, or the exact angle it has turned. Typically, encoders are really small and spin at high rates. To investigate how they work, we made larger slower models of them. This project demonstrates how incremental, quadrature, and absolute encoders work. Construction Encoder Disk A rotary encoder is a wheel with slits that is attached to the shaft of a motor (or other device that you want to monitor the position of). Our encoders were 3D printed. Structure Our structure is made out of OpenBeam. We wanted something sturdy and adjustable. We wanted to be able to move the sensors up and down to align with each other and closer and father away from each other if needed. The mounts for the motor and sensors were made for OpenBeam, but you can use other materials you have. Sensors We used Adafruit's break beam sensors. You could use LDRs and LEDs. The transmitter just needs to be powered. It can be powered with 3.3-5V. We use 2 AA batteries. The black is ground and the red is power. The receiver has a white wire. This is the signal wire. which goes to digital pins 5, 6, and 7 of the Arduino. We power the receiver via the Arduino (you can power both the transmitter and receiver via the Arduino ). Motor We have a larger motor and a motor controller wired to a 9V battery. You can use a smaller motor and a potentiometer to control the encoder. Just watch out for the voltage rating on the motor and change the diameter of the opening to fit your motor. Troubleshooting The break beam sensors use IR that can sometimes transmit through the material you are using. We had to paint our 3D printed material. The cardboard worked just fine. We had a bad crimp causing one break beam to always ride high. Using a multimeter, we determined there wasn't a short on the board or an issue with the code. Alternative Materials For the detectors, you can replace the break beams with LEDs and LDRs. The motor we used was one we already had. Smaller motors will work too. You don't need OpenBeam. You can make the stand out of things you already have around your house/workshop/classroom. Motor Controller Wiring on bottom of receiver. Wiring on bottom of transmitter. Transmitter setup Receiver setup Lesson Plan and Activity Description of how encoders work. Materials Needed List of Materials Simple Version (Breadboard): Breadboard Jumper wires Arduino 3 Break beams - https://www.adafruit.com/products/2167 3 Types of encoders Motor Stand Our Soldered Version: 3 Break beams - https://www.adafruit.com/products/2167 Motor - https://www.amazon.com/RS-550s-18v-Electronic-Controlled-Replacement/dp/B00TE42PME/ref=sr_1_1?ie=UTF8&qid=1477015531&sr=8-1&keywords=rs550 Arduino Motor Controller - https://www.amazon.com/uniquegoods-Controller-Adjustable-Reversible-1203BB/dp/B00RYRXFW2/ref=sr_1_11?ie=UTF8&qid=1477015447&sr=8-11&keywords=dc+motor+controller OpenBeam - https://www.amazon.com/OpenBeam-Starter-Construction-Clear-Anodized/dp/B0196FGLWK/ref=sr_1_20?srs=12712647011&ie=UTF8&qid=1476480862&sr=8-20 Connectors and Crimps - http://www.digikey.com/product-detail/en/jst-sales-america-inc/XHP-2/455-2266-ND/555485 -http://www.digikey.com/product-detail/en/jst-sales-america-inc/B2B-XH-A(LF)(SN)/455-2247-ND/1651045 -http://www.digikey.com/product-detail/en/jst-sales-america-inc/B3B-XH-A(LF)(SN)/455-2248-ND/1651046 -http://www.digikey.com/product-detail/en/jst-sales-america-inc/XHP-3/455-2219-ND/1651017 -http://www.digikey.com/product-detail/en/jst-sales-america-inc/SXH-001T-P0.6/455-1135-1-ND/527370Hookup Wire - https://www.sparkfun.com/products/11367Header pinsSolderProtoyping board - https://www.amazon.com/Snappable-BreadBoard-Scored-Boards-2-Layer/dp/B00PX52C7Q/ref=sr_1_14?s=industrial&ie=UTF8&qid=1477159972&sr=1-14&keywords=busboard Screw Terminal -https://www.sparkfun.com/products/105719V Battery9V Battery clip2 AA BatteriesAA Battery Holder Tools for soldered version: Crimper - https://www.amazon.com/Engineer-PAD-11-Precision-Crimping-Interchangeable/dp/B00IWD9XT6/ref=sr_1_6?s=hi&ie=UTF8&qid=1477165132&sr=1-6&keywords=interchangeable+crimper Soldering iron - https://www.sparkfun.com/products/11704 Screw driver for terminal Wire stripper

With this file you will be able to print Encoders with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Encoders.