Ender-2/3 CR10 (bowden) Titan extruder mounting bracket

thingiverse

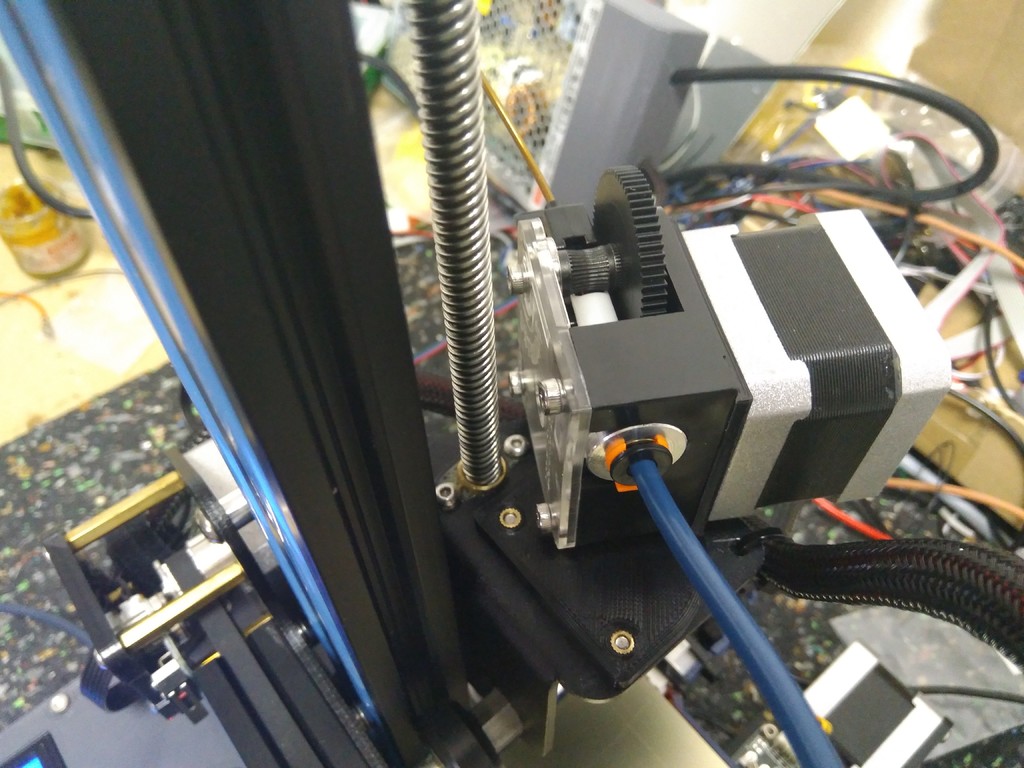

This is a bracket to allow mounting of a standard (non-mirrored) Titan extruder in the place of the stock extruder. Only tested on an Ender-2, but I have strong suspicion it would just work on CR10, Ender3 etc that use the same Z system. Instructions for Ender2 1. (optional) Swap the Z stepper with the stock extuder stepper - you don't need such a big stepper for the geared Titan and by doing that swap, you will make things more compact and more quiet too! 2. (optional) if you do 1, also lower the Vref of the extruder stepper driver from the factory 0.7x V to around 0.5x V (similar to the factory setting for X and Y).to avoid the stepper getting too hot .. 3. Mount the Titan to the bracket as shown on the pictures 4. Use M3x6mm screws to self thread the bracket from bellow to the Z carriage. 5. (optional) Use pigtail to tie the X cable to the bracket 6. (optional) Once happy, you may shorten the bowden tube a bit as an added benefit 7. You will need to change E-Steps to 420 and to reverse stepper direction. - If you have the bootloader flashed and custom firmware loaded, you can do it from there. For TH3D look in Configuration.h and uncomment: ```#define TITAN_EXTRUDER``` ```#define TITAN_EXTRUDER_STEPS 420``` For non-TH3D Marlin: ```#define INVERT_E0_DIR false``` ```#define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 400,420 }``` - If you are still using the stock firmware and don't want to flash. you will need to add to startup G-Code: ```M92 E420``` (in Cura it's Settings->Printer->Manage Printers->Machine settings); And additionally, you need to swap the wires inside the E stepper connector - in theory you can use an exacto knife to carefully lift the plastic that locks the pins inside the connector and free them up to pull them off the connector, then just push them back in, but in swapped order. Like if logically they were in order 1x23x4 inside the connector, you make it 4x32x1; as if you were plugging it rotated 180 deg, but as this is not possible because the connector is directional, you rotate the wires inside instead As for print settings, definitely DON'T!! use PLA, as it would deform with the stepper getting warm .. Use PETG instead. You can use like 20% infill but in order to make the the vertical part stronger, set walls to 1.6mm so it prints at 100% infill with that little trick (it's 3mm thick). As usual FreeCad source ans STEP files included .

With this file you will be able to print Ender-2/3 CR10 (bowden) Titan extruder mounting bracket with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Ender-2/3 CR10 (bowden) Titan extruder mounting bracket.