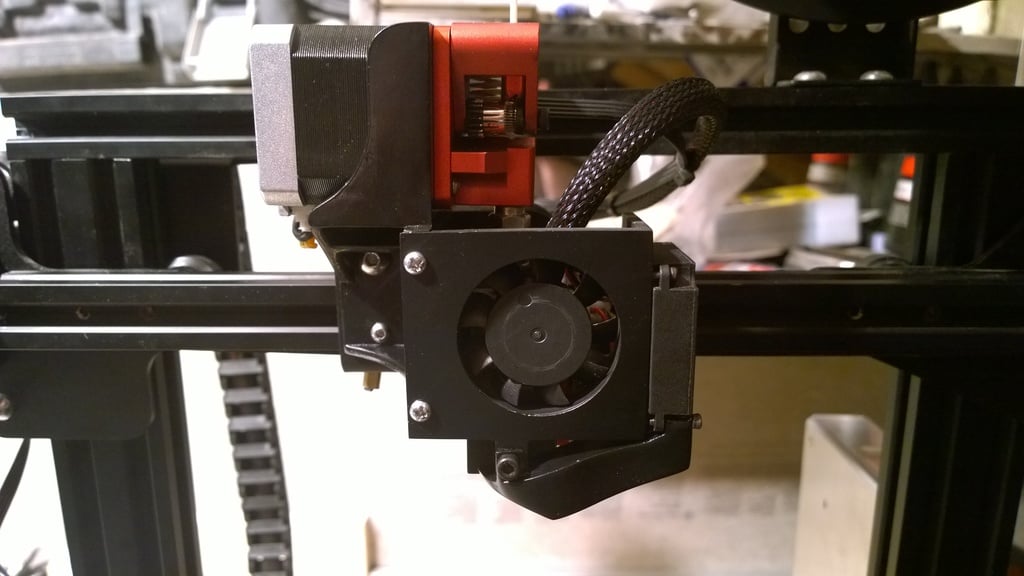

Ender 3 MicroSwiss Direct drive extruder kit

thingiverse

Ender 3 Direct Drive Extruder Kit ====================== Designed for Use with All Metal Hotends from MicroSwiss and Aluminum Dual Drive Extruders. **Benefits of This Kit:** + Works seamlessly with microswiss and aluminum dual gear extruders. + Eliminates the need to run filament through the bowden tube, allowing for more precise filament control and preventing all metal hotend gunking up easily. (2mm retraction causes no stringing). + Removes airflow from heatsink fan, enabling you to control parts cooling with greater accuracy. + Clears stepper and extruder from top horizontal bar without affecting build height at all. + Enhances consistency by providing parts cooling from 2 sides. + Can be printed without supports. + Can be done for just the cost of the filament (approximately 80g). + Features a slot for a mini 24 to 12v converter, combined with meanwell psu, making the printer virtually silent. + Extrudercoolingfan.stl can be easily removed without removing the part cooling fan by undoing a single screw that holds it to the ExtruderFanmount.stl for changing nozzles. **Downsides:** + Plastic is more flexible than aluminum and steel. + PETG will disfigure when it reaches 75c and over. + Requires cutting around 4cm off your bowden tube for this extruder. + Requires extending your 4 core stepper cable by approximately 50cm. **Warning:** 3D printed direct drive kit necessitates the stepper motor cable to be extended. You can do this in any way you prefer, but you will need about 50 centimeters of additional 4 core cable if you want to fit it together with the extruder heating and fan cables. You will require around a 4cm piece of bowden tube. If you're not comfortable cannibalizing your current tube as reverting to the old extruder would become more difficult, you'll need to buy some spare. I recommend slightly enlarging screw holes until the screws drive in without too much force. Added pictures of the ASA reprint for all the parts. These were wet sanded with 150 grit sandpaper, sprayed with TAMIYA fine surface primer and TAMIYA black spray paint. ASA is not as rigid as PETG though, but it finishes better and smoother. **Assembly Instructions in Pictures:** Cable chain end attachment remix allowing better cable management: https://www.thingiverse.com/thing:4457470 Cable chain thing to print with it: https://www.thingiverse.com/thing:2920060 **Update 1:** All 3 models have been tweaked slightly. Extruder.stl now has a flat cable clip for the stepper cable. Extrudtercoolingfan.stl has the air nozzle distance increased from the heater block as I found that the PETG duct had a slightly deformed edge. Extruderfanmount.stl has a small upwards lip added to further direct the heatsink fan airflow away from the print. If you're printing up to 240c, you don't need the extrudercoolingfan.stl upgraded. I started printing ASA at 255 and the PETG part deformed.

With this file you will be able to print Ender 3 MicroSwiss Direct drive extruder kit with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Ender 3 MicroSwiss Direct drive extruder kit.