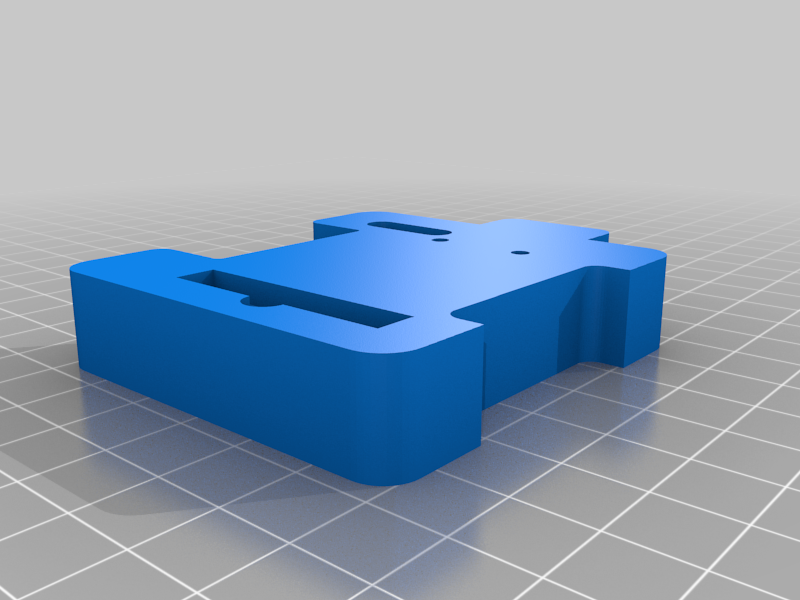

Ender 7 Biqu H2 Mount

thingiverse

This is a remix of a baseplate to fit on Ender 7, uses four M3x8 DIN7991 screws to secure extruder on mount (Will require more for modules!), to secure mount to the carriage you can reuse original screws that holds fan case. Link to updated original model: https://www.printables.com/fr/model/186618-modular-biqu-h2-mount-for-single-or-double-5015-fa You can use other modules from original mount design as well (Except cable manager, I was too lazy to make a mount for it, but you can use carriage hole for this purpose). You can also refer to <a href="https://www.youtube.com/watch?v=TFctt7043uc">this video from Embrace Making</a> for dissasembly assistance, it helped me so much when I was trying to do this I've tested it on all-metal version with dual-fan setup, you can refer to my klipper config if you need to (Please note that I use Octopus Pro, your pins will be different if you use some other motherboard): <code> [stepper_x] step_pin: PF13 dir_pin: PF12 enable_pin: !PF14 microsteps: 16 rotation_distance: 64 endstop_pin: ^PG6 position_endstop: 0 position_max: 225 homing_speed: 80 [tmc2209 stepper_x] uart_pin: PC4 run_current: 2.0 stealthchop_threshold: 999999 [stepper_y] step_pin: PG0 dir_pin: !PG1 enable_pin: !PF15 microsteps: 16 rotation_distance: 64 endstop_pin: ^PG9 position_endstop: 225 position_max: 225 homing_speed: 80 [tmc2209 stepper_y] uart_pin: PD11 run_current: 2.0 stealthchop_threshold: 999999 [stepper_z] step_pin: PF11 dir_pin: !PG3 enable_pin: !PG5 microsteps: 16 rotation_distance: 8 endstop_pin: probe:z_virtual_endstop \# position_endstop: 0 \# endstop_pin: ^PG10 position_max: 300 [tmc2209 stepper_z] uart_pin: PC6 run_current: 0.650 stealthchop_threshold: 999999 [extruder] pressure_advance: 0 max_extrude_only_distance: 1000.0 step_pin: PG4 dir_pin: PC1 enable_pin: !PA0 microsteps: 16 rotation_distance: 3.4334 nozzle_diameter: 0.400 filament_diameter: 1.750 heater_pin: PA2 sensor_type: MAX31865 sensor_pin: PF8 spi_software_miso_pin = PA6 spi_software_mosi_pin = PA7 spi_software_sclk_pin = PA5 rtd_nominal_r: 100 rtd_num_of_wires: 2 rtd_reference_r: 430 rtd_use_50Hz_filter: True control: pid pid_kp: 11.447 pid_ki: 0.245 pid_kd: 133.924 min_temp: 0 max_temp: 500 [tmc2209 extruder] uart_pin: PC7 run_current: 0.800 stealthchop_threshold: 999999 [heater_bed] heater_pin: PA1 sensor_type: EPCOS 100K B57560G104F sensor_pin: PF3 control: pid \# tuned for stock hardware with 50 degree Celsius target pid_kp = 74.146 pid_ki = 1.521 pid_kd = 903.658 min_temp: 0 max_temp: 130 [bed_screws] screw1: 25, 33 screw2: 225, 33 screw3: 225, 225 screw4: 25, 225 [fan_generic extruder_partfan] pin: PA8 [fan] pin: PE5 [mcu] serial: /dev/serial/by-id/usb_serial_1 restart_method: command [mcu rpi] serial: /tmp/klipper_host_mcu [adxl345] cs_pin: rpi:None spi_speed: 2000000 spi_bus: spidev2.0 axes_map: -y, x, z [resonance_tester] accel_chip: adxl345 accel_per_hz: 70 probe_points: 125,125,10 [input_shaper] shaper_type_x = mzv shaper_freq_x = 44.4 shaper_type_y = mzv shaper_freq_y = 56.4 [filament_switch_sensor filament_sensor] pause_on_runout: true switch_pin: !PG12 [printer] kinematics: corexy max_velocity: 500 max_accel: 5000 max_z_velocity: 10 max_z_accel: 1000 square_corner_velocity: 5.0 [include timelapse.cfg] [bltouch] sensor_pin: ^PB7 z_offset: 1.5 control_pin: PB6 x_offset: 52 y_offset: 0 samples: 2 [safe_z_home] home_xy_position: 73, 112.5 # Change coordinates to the center of your print bed speed: 100 z_hop: 10 # Move up 10mm z_hop_speed: 5 [bed_mesh] speed: 100 horizontal_move_z: 10 mesh_min: 52, 0 mesh_max: 225, 225 probe_count: 5, 5 </code>

With this file you will be able to print Ender 7 Biqu H2 Mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Ender 7 Biqu H2 Mount.