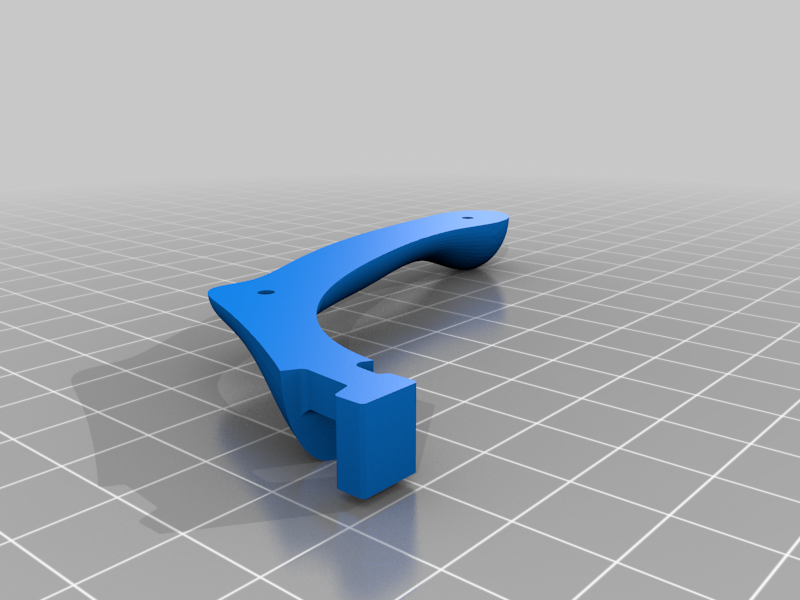

Epoxy Tip Off Handle

thingiverse

Epoxy tip off handle: in order to get the best surface finish when using epoxy to build up barrier coats, tipping off is completed by dragging a section of a roller over the rolled epoxy. I made this handle and adapters to make it easy to hold the foam roller sections. The handle will just slot into the adapter for easy switching between rollers when the epoxy starts to kick off. Note: The adapter is designed for a 38.5mm inner diameter roller which I assume is standard. Note: The adapter may not fit the handle well depending on the tolerances of your printer. If this is the case try scaling the adapter and reprinting. I had a tolerably loose fit but wanted to try getting a perfect fit. I scaled the adapter down to 95% and it no longer fit so I would recommend starting with 1-2% scaling up/down depending on how far off the fit is. Printing: I used PLA with a 0.6mm nozzle at 215C. Infill: I used 15 but you could increase or decrease depending on application. Perimeters: 2 Assembly: The handle is printed in two halves and has small holes on the contact faces. These should fit a 6mm long cutting of 1.75 filament and help to align halves. I used contact cement to attach the handle halves as well as to attach the adapter to the foam roller section. However, crazy glue or any other glue that works on plastic will work and may be better since contact cement does not allow for aligning after halves are put together.

With this file you will be able to print Epoxy Tip Off Handle with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Epoxy Tip Off Handle.