Excel spreadsheet to determine workable T-O-M feed rates

thingiverse

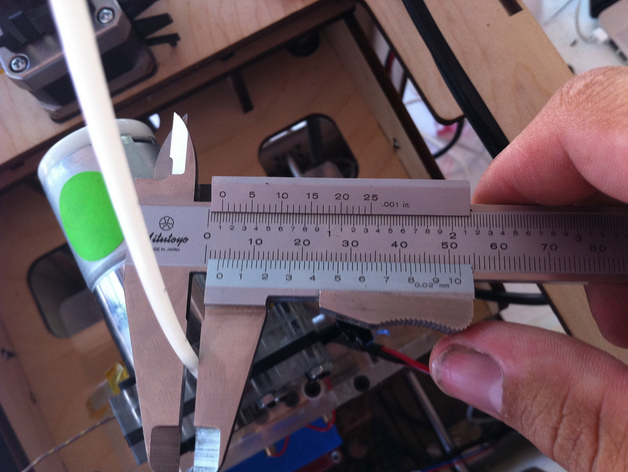

This spreadsheet calculates optimal feed rates for your TOM using W/T and layer height you specify. Flow rate is fixed at 255 PWM due to extruder firmware limitations. The spreadsheet also helps determine actual flowrate. It's a work in progress, so use it at your own risk. Made for stock TOM, except fan duct and relay for DC motor. To use the spreadsheet: 1. Measure feed rate of filament into extruder (mine was 20mm intervals, averaged and divided by 20). 2. Measure and input filament diameter (mine was 2.92mm) and extruded filament diameter (0.6). This calculates the flow rate. 3. Note that around 13% of volume is lost during extrusion (based on observations, may vary). Repeat step one and measure lengths of extruded filament for each marked interval (mine was 221.7mm for 10mm of filament going in), then average these lengths. 4. Divide actual flow rate by predicted flow rate to get the ratio (mine was 0.8716, but currently best ratio is 0.85). 5. Input desired layer height and W/T values, plus approximate flow rate. The last box will show the feed rate required for nice printing. For testing, I used a fresh SF profile with only spreadsheet values as modifications. Adjust raft settings, outlines, and first object layer feed rates to your preference. Temperature was set at 225C. Results showed minor adjustments needed for Z starting height and feed rate. Be gentle if you find errors!

With this file you will be able to print Excel spreadsheet to determine workable T-O-M feed rates with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Excel spreadsheet to determine workable T-O-M feed rates.