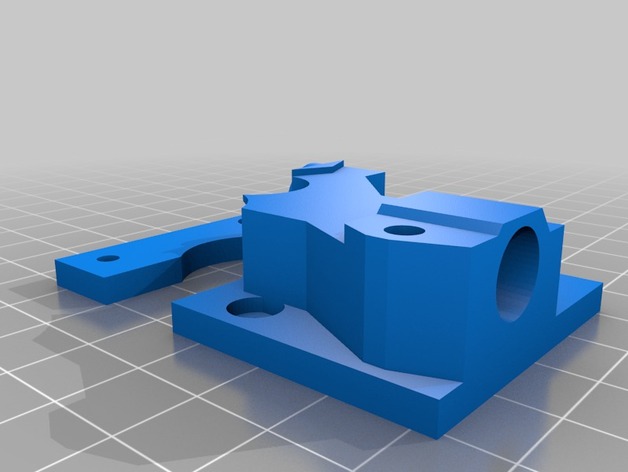

EZFlex Planetary Extruder

thingiverse

A remix of Nylocke's EZFlex extruder, which is a direct replacement for Seemecnc's Ezstruder, but modified to work with a planetary geared motor. The bowden tube runs all the way to the hobbed gear, allowing this to be used with flexible filaments. Nylocke's original design: https://www.youmagine.com/designs/ezflexstruder NOTEs: In the picture, the screw at the top left has an absurd amount of nuts on it only because it was too long and I couldn't find a shorter one while putting this together. Also, the passthrough connectors have a little play in them, so a twist tie wrapped around the locking collet to keep it from jiggling is handy. Instructions Rough Bill of Materials: Planetary Geared Nema 17 motor, recommended gear ratio of 5:1 M7 hobbed gear for 8mm shaft, I recommend the one from TriDPrinting, it's excellent Printed Adapter Printed Arm Printed Body (called plate in the current file name) 1x M8x20ish bolt 2x M8 washer 1x Passthrough bowden connector, from E3D or DTA-Labs 1x 608 bearing 1x ezstruder spring (need to figure out the exact specs) 4x M3x12 screws (I think that's the correct length, will check) A handful of long (30mm or longer I think) M3 screws (I'll figure this out too) A handful of M3 nuts 1x small ziptie ASSEMBLY: 1) Print all three pieces. The arm will need some support material. 2) Screw the adapter onto the motor using the M3x12 screws. There's a gap one side of the adapter, that's the side the bearing will be on later. 3) Assemble the bearing arm: a) push the 608 bearing into the retaining slot on the arm b) push an M8 washer in above and below the bearing c) with the bearing and washers lined up, push the M8 bolt down through them...the plastic should keep the bolt in place, but if your printer made the holes loose, use an M8 nut on the end 4) Screw the main body of the extruder down onto the adapter. The gap in the adapter has to be on the left as you drop the body down over it. 5) Screw on the bearing arm, and wedge in the spring. The ziptie goes around the spring side of the arm, pulling it flush against the body of the extruder, since the spring will try to angle it out a little. This might not be 100% necessary, but it will guarantee that the bearing presses flat against the filament. 6) Screw in the pass through bowden connector. 7) Install the bowden tube. To make sure it's easy to start filament through it, use a knife and give the inner edge of the top of the tube a slight angle. The current design is a little tight, so you'll have to fight with the tube to get it all the way up through, but it'll hold well. 8) Install the hobbed gear on the motor shaft, and be sure to line up it up with the bowden tube. Done! Mount it to any EZStruder compatible mount, and feed filament down through the bearing arm. Congratulations, you now have a bullet proof, easy to load and unload extruder with ****tons of torque, go you!

With this file you will be able to print EZFlex Planetary Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on EZFlex Planetary Extruder.