Filament Coil Holder for Lulzbot Mini (remix)

thingiverse

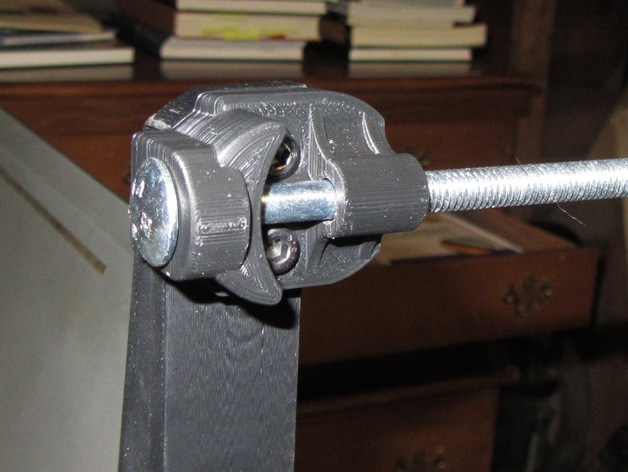

The stock filament holder for the Lulzbot Mini is basically a printed stick and it works fine most of the time, but I did have the filament in a couple long overnight print jobs get jammed because the printer had to tug hard on the filament to overcome the friction between the spool and the stock coil holder. So I decided to replace it with something a little better. I used the spool centers and knob without modification from this project: http://www.thingiverse.com/thing:219667 The skate bearings had a nice snug "tap 'em in" sort of fit. I had to use epoxy on a 5/16" nut for the knob. I printed the knob pointy side down with a brim -- the wide end is a thing of beauty. I was skeptical it would print OK, but it came out awesome. Then I made a bracket to replace the stock holder -- my bracket holds a 5/16" carriage bolt (round head with a square section underneath (2d photo)) and then those spool centers slide on and the knob with captured nut screws it all down. The bracket I made is a little overwrought, but I was using it to work on my (weak) FreeCad skills. Despite that, it works great -- my overnight print jobs no longer suffer from the filament jamming itself tight into the spool. If anything, it spins a bit too free now and when printing fast, it can sort of unspool a bit extra. I used an 8" carriage bolt but clearly, a 7.5" would have been ample. The bolt's hole in the bracket will need to be bored most likely, mine did - use a 5/16" bit of course. The square hole on the backside should be snug enough to hold the bolt in place (tap it in while the piece is still warm or use the captured nut to pull it tight -- if loose, there is always epoxy) but you could also put a nut out in front if you want -- it isn't really necessary unless the carriage bolt is loose and wants to fall out. When the nut knob is tightened down, it holds the whole pancake together. The spool centers have skate bearings in them. I had some laying around so I used those, but I think you could just fill the central holes and then make a 5/16" +smidge hole through them and go without the bearings. You'd also want to get some nylon washers in this case, or print up some washers. That might be the perfect balance that prevents unwanted unspooling at speed and also prevents excess drag. The source files are included -- it's FreeCAD's native file format. I've also included just the basic hole pattern for the stock spool arm if you want to make your own filament support entirely. The screws fit snugly, might need to be worked through with a hex but they line up with the screw holes on the Lulzbot part perfectly. The holes aren't perfectly centered in the block -- one side meets the top of the Lulzbot part without sticking up or down -- what I mean is that the top of the bracket is even with the top of the Lulzbot part. I could have made the block wider and centered the stuff -- don't know why I didn't. You can though if you like.

With this file you will be able to print Filament Coil Holder for Lulzbot Mini (remix) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Filament Coil Holder for Lulzbot Mini (remix).