Filament monitor for Replicator 3D printer

thingiverse

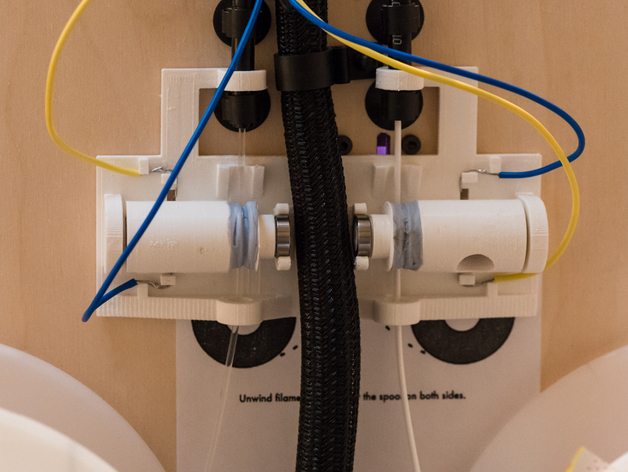

This project combines a physical filament monitor, simple electronics, and a Twine to create a monitor that emails you with printer status: fully operational, filament feed stopped, or printer stopped. It consists of three components: 1) a filament movement monitor using a small cylinder mounted on ball bearings with a magnet in the rotor triggering a reed switch; 2) an interface circuit powered by the Twine's breakout interface and detecting rotation for all practical feed rates; 3) Twine email messaging activated when placed on the printer top, alerting you of operational status, printer stoppage, or filament feed disturbance. All materials can be sourced from Jaycar in Australia, Hearn's Hobbies, and Supermechanical for less than $20.

With this file you will be able to print Filament monitor for Replicator 3D printer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Filament monitor for Replicator 3D printer.