Filament Straightener

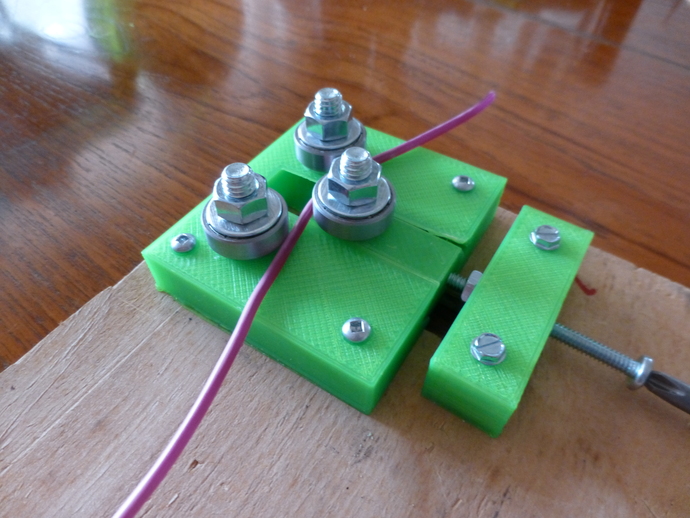

thingiverse

Those last few meters of filament on small-diameter rolls drive me nuts! Coiled so tightly I can barely get it off by hand, it always causes problems for my printer. Tired of trying to uncoil and straighten those tight little loops by hand, I created this Filament Straightener. It is, obviously, modeled on wire straighteners, but uses printed parts and is sized for filament. Pictures show before and after of tightly coiled filament. The after was put back on a reel for easy printing and worked great! This design was done using FreeCAD. As an experienced OpenSCAD user, I find FreeCAD a very satisfactory alternative that I am choosing more and more often for new designs. The FreeCAD files are included; STEP format files are also included. This is similar to, but not derived from, http://www.thingiverse.com/thing:30733 . Instructions Bill of Materials One of each of the stls. I used PLA with 40% infill. 3 ea. 608 bearings. 3 ea. 5/16 x 1 1/2in.€ or M8 x 40mm bolts. 6 ea. matching washers. 3 ea. matching nuts. 6 ea. #6 x1 1/4in.€ sheet metal screws (not sure of the metric for these?). 1 ea. #10 x 2in.€ÂÂ, or M5 x 50mm screw (all thread if possible). 2 ea. matching bolts. Base for mounting. I used 1/2in.€ plywood that I had on hand. Needs to be big enough to clamp or hold while filament is being straightened. Use the straightener body as a template to mark locations of the heads of the two large bolts. Drill the holes with a diameter and depth to provide clearance for the heads. (Not critical.) With the body in the same position, mark the groove needed for the bolt head on the slider. Allow a little extra on each side to clear the head and use a coping saw or saber saw to cut the groove. (Not critical. Mark the holes for the four body mounting screws and drill pilot holes if needed. Put one of the bolts through the body, put a washer on it, then a bearing, another washer, and the nut. Tighten the nut firmly. Repeat for the other body bolt and the slider bolt. Put the slider into the slot in the body and secure the body to your base using four of the screws. Press a nut for the long screw into the pocket in the tensioner and thread the long screw through it. Put the other nut on. This is a lock nut to keep the tension constant. Position the tensioner a small distance from the body (about the width of the lock nut or so) and use the last two sheet metal screws to anchor it. Your straightener is ready to use. To use your straightener, put the end of the filament to be straightened between the bearings as shown in the photo. Tighten the tensioner bolt as desired, then pull the filament through. Adjust until you get the desired result. If a significant straightening is desired, often it is better to do it in a few steps using multiple passes, rather than trying to do it all at once.

With this file you will be able to print Filament Straightener with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Filament Straightener.