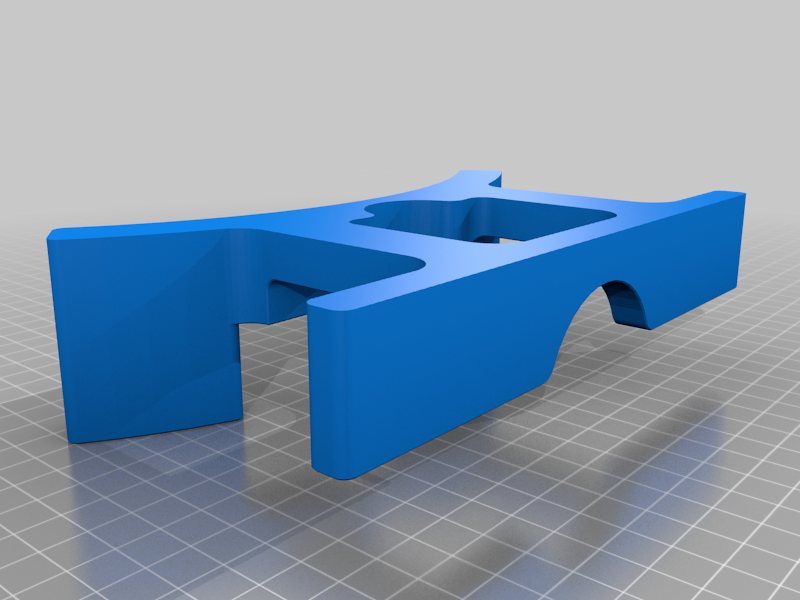

Filament Welder 1.75mm

thingiverse

This is a tool for welding 1.75mm 3D Printing Filament. Use this tool along with a 6.25" piece of PTFE tubing (same as used on Boden type printer) and a common tea light candle as the heat source. The tool is meant to clamp to the edge of a table. Clamp to the top (Most common) for less heat or to the bottom for more heat.. Bill Of Material: welder_base_v2 3D print with no supports 1 common tea light candle 6.25" (157mm) PTFE tubing (OD=4mm, ID=1.8mm) Assembly: 1.Cut PTFE Tube to length 2.Use the end of a pen or awl to gently open up ends after cutting 3.Insert Tubing into slots 4.Use 1 or 2 clamps to mount to edge of table Tools: Clamp Lighter Timer (phone or stop watch) Procedure: 1. Cut 2 ends of filament at 45 degree angles. 2. Insert end of filament into left and right ports. Each segment can be on a roll or open as desired. 3. Push ends into ports so that the 45 degree ends meet in the middle of the boden tube directly under the candle. 4. Have a stop watch or timer ready to start. 5. Light the candle and start the timer. 6. Place a slight pressure on the filament ends and allow to heat for 1 minute. 7.After 1 minute slightl twist or rotate the filament with a light pressure. This enhances the weld. Practice makes perfect. 8.Remove the candle heat. Either move the candle out from under or simply blow out 9.Wait 1 minute to cool. Do not agitate the connection at this point. 10.After 1 minute. Place a slight alternating compressive pressure to each end of filament. When the filament has cooled enough you should feel a slight amount of give. Even better you may feel it release. 11. Slide the filament back and forth in the tube using both compression and tension. You will feel a slight resistance which should decrease after a few cycles. 12. Pull the connection through the welder and onto the spool or the direction you want to keep your new connection. 13. Inspect the weld. It should be continuous with no overhangs, or diameter changes. If there is a color change there should be some color mixing at the weld. 14. If both ends were on a spool, there are slots in the base which allow the PTFE tube to be removed. The tube can travel with the filament and even stay on during a print session until all the filament is used up. Applications: *Make use of partially used spools of filament rather than waste *Attached multiple colors in sequence create multi-color prints Software: See pylen filament usage utility. This utility generates filament layer usage data which can be used to calculate the cut lengths for the filament. The tool works with your gcode files generated by the Cura Slicer. https://github.com/bmoniey/pylen On GrabCAD: https://grabcad.com/library/3dprint-filament-welder-1

With this file you will be able to print Filament Welder 1.75mm with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Filament Welder 1.75mm.