Filawinder Filament Guide System v2.0

thingiverse

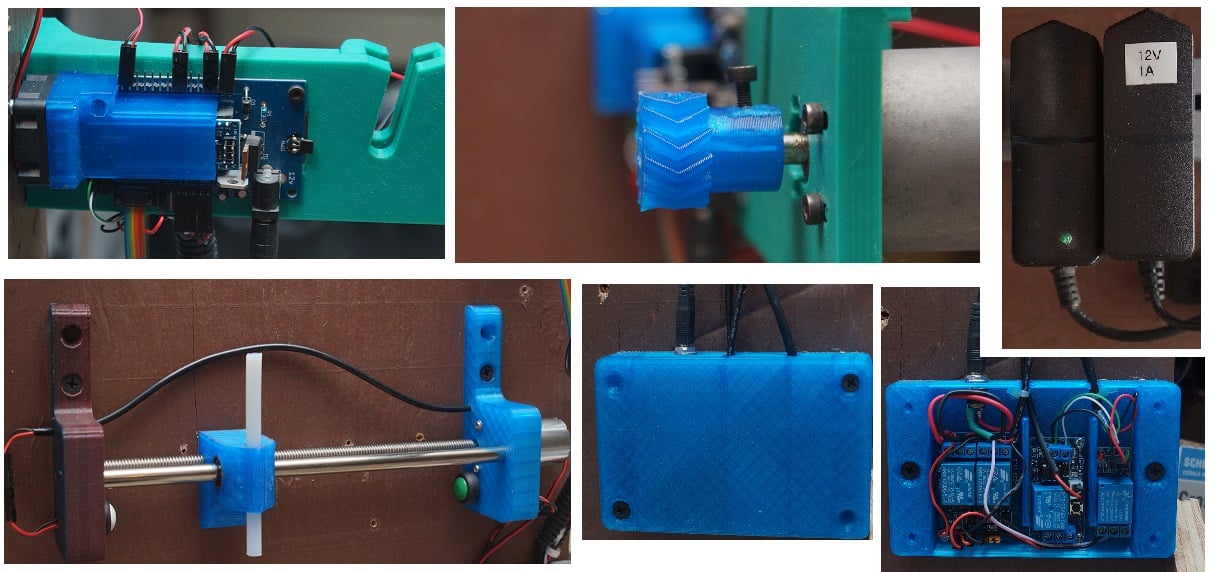

December 22 Updates: Center piece guide now features two holes for 6mm and 4mm PTFE tubes to pass through. Switching to 5-8mm flex couplers commonly utilized in 3D Printers has necessitated adjustments to the left and right frames. Spool gear and drive gear have been updated to bring the magnet closer to the sensor. The drive gear must fit snugly, with no retaining screws used. Doing a favor for yourself might involve 3D printing the large spool; a hole on its side affects the distance to the magnetic sensor. If too far, rotation may not register. System functions well. Firmware changes are final (I believe). MOTOR: Any motor resembling the pictured one will work. You'll need to determine how to attach it to the threaded rod. I used a 5mm to 8mm coupler for this purpose and achieved great results if properly centered. Here's how this system works: When the spool completes a full turn, the 5V relay activates the motor that moves the guide. The distance the guide travels depends on how long the relay remains active; this duration can be altered in the firmware. A 25RPM motor set to 3 seconds will move approximately 1.75mm, giving you an idea of what to expect. Once the guide reaches either end of the rail, it triggers a momentary button placed at each end, reversing the motor's direction. http://soliforum.com/i/?iAI3WRn.jpg The threaded rod passes through the nut situated inside the guide piece. When the motor turns, the guide moves by virtue of the nut within it. Momentary buttons on either end activate a very special relay (bistable). This relay triggers the [two-channel relay] that reverses direction. Required Materials: A second 12V 1A power supply to drive the 2-channel relay and motor separately. 12v 2-channel relay (basic) 5v bistable relay (connect terminals, and it closes; connect again, and it opens) 5v relay (basic) Motor Two momentary push buttons 8mm diameter threaded rod and a nut. The length of these rods is chosen based on the distance the guide needs to travel. A wider spool requires longer travel. Rods are approximately 220mm long. 8mm smooth rod Linear motion bearing LM8UU (located inside the guide) 12V 30x30x10 cooling fan (optional). If a cooling fan mount is used, consider printing my custom drive gear for needed clearance. Screws, wires, connectors, and a soldering tool if you prefer not to deal with connectors. This is the relay wiring diagram and the types of relays I used. http://soliforum.com/i/?qPoWHij.jpg

With this file you will be able to print Filawinder Filament Guide System v2.0 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Filawinder Filament Guide System v2.0.