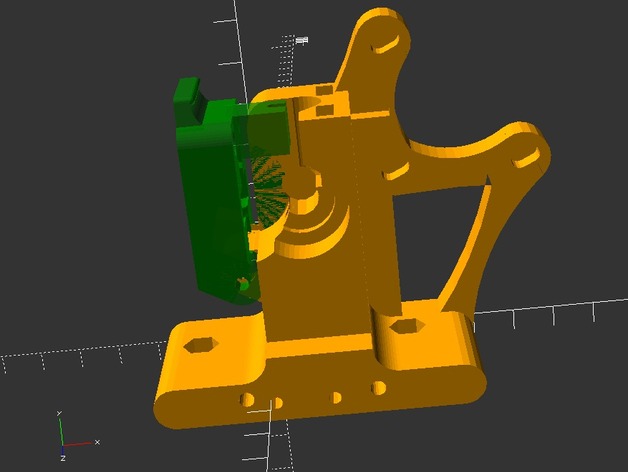

Flexy-fixed Greg's Wade's Extruder

thingiverse

This is a minor tweak to AndrewBCN's extruder that reduces the gap between the pinch and the filament channel significantly. Too large a gap here lets flexible filaments like NinjaFlex or PolyFlex twist and push out of the extruder from the side instead of being forced down into the hot end properly. With this smaller opening, the flexible filament doesn't have a chance to escape. I also made the filament guide wider on one side because the tips were too narrow to print reliably and cleanly when configured for 3mm filament. It should be wider on both sides, but I need to carve out space for it on the extruder body first before it will fit. This thing is managed on github as well. November 12th, 2015 Update 1: The .scad file is set up for 1.75mm filament by default and the .stl files are built for both 1.75mm and 3mm filament extruder configurations. I corrected the STL so that the 1.75mm version guide will lay flat on the print bed, but I haven't tested it out yet. Let me know if you run into any issues with it. Also, I renamed the files to match this thing's name and avoid confusion with AndrewBCN's version altogether. How I Came Up With This Design I found the original idea for this solution in a video by Christopher Hoffman which explains the original problem quite well too. I tried to use his fix by modifying my original Wade's Greg's extruder, but it turned out wrong because I was using a hand drill and wasn't very precise myself.

With this file you will be able to print Flexy-fixed Greg's Wade's Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Flexy-fixed Greg's Wade's Extruder.