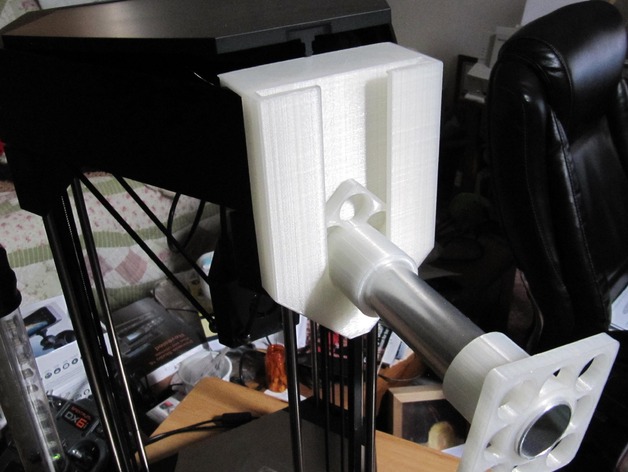

Flux Delta external filament spool holder

thingiverse

Flux Delta printers have a recess for smaller spools, but a one kg spool won't fit. This spool holder is designed more-or-less on the fly to hold larger spools. It clips over the front (relative to the cover hinge) and is slightly sloped on the back side to prevent interference with the extruder carriage. The back side of the clip fits precisely over the cover latch and is sized to fit equally well on the top of the printer. There is very little movement or play in the clip portion. I suspect that one could add a layer of masking tape to make a firmer fit. The SCAD files are included, but be warned. I am not a programmer. I will never say I know what I'm doing. I've been learning OpenSCAD with each model I construct and I try to implement common accepted practices in my code. There may be duplication of code in these files. There are certainly references from one part to the other and there's no automation to ensure that when a value is changed in one that it will be adjusted in the other. I can assure that such changes will not happen. This model has been created to fit my printer and my printer settings. To get this far, I frequently chopped off portions of the model in OpenSCAD to print and test fit. Three or four partial prints for the top clip, two partial prints for the "socket" for the spindle and three prints to ensure that the spindle would fit the scrap aluminum I have in my scrap pile. I cut the tubing to six inches long to allow me to drill holes for clips or pins to retain the spool. The tubing in this model is 1.125 inches diameter, although the code will not reflect that figure. This is a result of the test print. I used a lot of TLAR to make this model. I suspect that one could make some modifications to the model to use with other printers. The design is far from optimal, but it looks like it's going to work. If not, I'll change something and build a variation. I can see in the published version that the preview portion of OpenSCAD is showing artifacts where none exist. I did not use the common "fudge" figure to make larger the difference actions, so there are "shadows" in the photos here that have no impact on the print, nor on the rendered model in OpenSCAD. It's my first contribution to Thingiverse and I hope others will make good use of it. Print Settings Printer: Flux Delta Rafts: No Supports: No Resolution: 0.250 Infill: 20% (arbitrary) Notes: Print two copies of the spindle, unless you use your own variation to retain the spool. Post-Printing Simple final steps I'll be adding epoxy to secure the tubing on the clip end. I'll be drilling holes at the opposite end of the tubing to accept retention clips (from my scrap pile). I could certainly build something via 3d printing, but why? Update to this build. I've found that the feed tube for the Flux Delta wants to "wander about" when connected to the external spool. There is insufficient height to the clip to drill a guide hole for the feed tube. One could increase the wall thickness and subtract a cylinder for the guide tube if desired. I routed the feed tube over the clip and stuck it in place with push-pins. Adhesive tape didn't stick well enough.

With this file you will be able to print Flux Delta external filament spool holder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Flux Delta external filament spool holder.