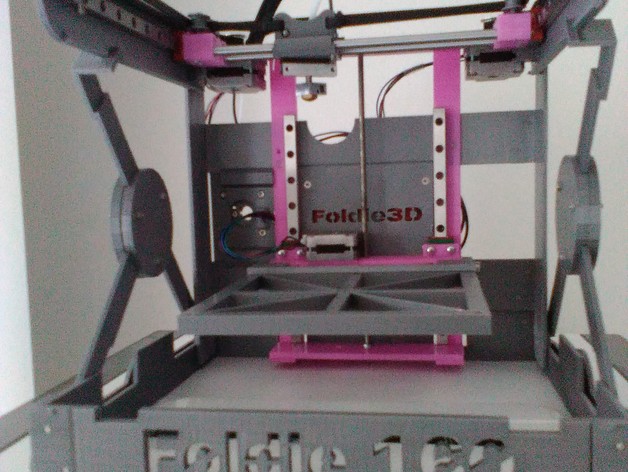

Foldie 3D FFF Printer

thingiverse

The text discusses various aspects of cryptocurrencies, particularly their potential benefits, drawbacks, and why Foldie (a fictional cryptocurrency project) is investing in them. The author argues that cryptocurrencies offer: * **Cross-border payments**: Like digital drink coupons, but for money, crypto allows global transactions without needing traditional payment methods. * **Lower transaction costs**: With blockchain technology, transaction fees are significantly reduced. * **Real-time transactions**: Unlike the days of waiting for a "transaction day," cryptocurrencies process transactions in real-time. **Security Concerns** Regarding security, the author stresses the importance of keeping sensitive information private and emphasizes that never sharing personal documents over the internet is crucial. He provides advice on: 1. Using open-source or white-label exchanges to minimize risk. 2. Avoiding uploading ID copies online by using verification methods other than submitting government-issued documents. **Why Invest in Cryptocurrencies?** The author's reasons for investing in cryptocurrencies include: 1. The potential for the cryptocurrency sector to stabilize after a correction (which is considered inevitable). 2. The importance of learning from the experience and becoming wiser. 3. The benefits of holding cryptocurrencies with real-world use cases or applications. By considering these factors, it becomes clear that the text aims to educate readers about the world of cryptocurrencies, their advantages, and their limitations while promoting responsible investing practices.

With this file you will be able to print Foldie 3D FFF Printer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Foldie 3D FFF Printer.