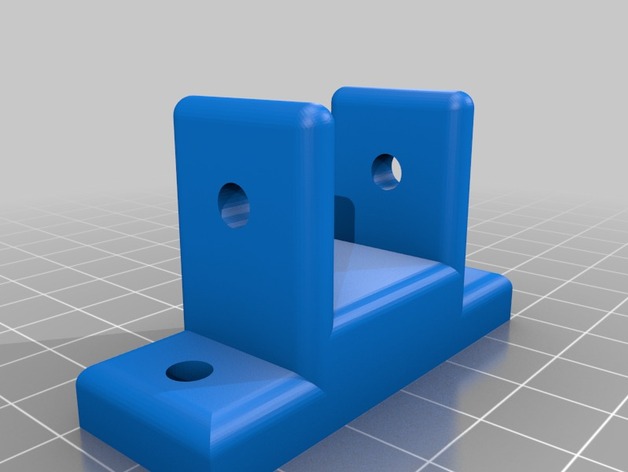

Folger Tech v-slot holder/spacer

thingiverse

This part is to upgrade the folger tech 2020 prusa i3 kit to have a v-slot Y axis. Its basically two corner brackets, only it accounts for going over the stepper in the back. My printer was pretty horrible with the bearings that came with it, and would actually do a skipping motion instead of sliding smoothly, so I decided to upgrade to the far superior v-slot. Instructions Parts Needed Various M4 screws, and tnuts to match 3 v-wheel kits from openbuilds.org part store, or similar 3 M5x25 screws for the vwheels 1 eccentric spacer from openbuilds.org 2 1/4" spacer 1000mm of v-slot from openbuilds.org part store Hack saw, miter saw, band saw, or something to cut v-slot with Step 1 On the side that has a single bearing, drill out the outer of the bearing-holder holes to 11/16th. This will be your eccentric spacer hole. Step 2 On the side with two bearing holders, drill out the two outer holes to 1/4th inch. These will be the holes for your non-eccentric mounted wheels. Step 3 Cut your v-slot with either a hack saw, or a miter saw. Precision doesn't really matter, as long as they're long enough to allow the spacers to screw into them. Shoot for somewhere around 16" long to span the length of the printer. Step 4 Put your wheels on, using your 1/4" spacers on the side with two wheels, and your eccentric on the side with only one. Make sure the eccentric spacer is as wide as it can be. Don't forget to add the shims! And don't over-tighten your nuts! Order for parts: screw -> spacer -> shim -> bearing -> wheel -> bearing -> shim -> nut Step 5 Put drop in t-nuts on the bottom of your spacers, as well as in the sides. Slide your pieces of v-slot into them, and place them on the frame of your printer. Put the bed out side of them, and push them outwards so that the wheels are a little loose, but not falling down. Step 6 To make sure that your axis goes straight back and not at an angle, use a caliper or tape measure to make sure that both the front and back ends of one of your vslot extrusions are an equal distance away from the outside frame of your printer. The goal is to get it parallel, so you know that your extrusion is heading straight back. Then, Tighten this one down if its near where you want it. With the second piece, push it out into the wheel on the other side so that its relatively tight. Then, measure between the first vslot piece and the second one and adjust it until it is an equal distance away in the front and the back. Tighten this one down, making sure the bed's wheels are resting inside of the v slot. Step 7 Adjust the eccentric spacer until your Y axis gantry no longer wobbles. Step 8 Enjoy having silky smooth, and quiet linear motion on your new, fancy Y axis!

With this file you will be able to print Folger Tech v-slot holder/spacer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Folger Tech v-slot holder/spacer.